第四章 真实世界#

CHAPTER 4 The Real World

真实世界是你我生活的地方。它不在这本书中,也不在某个模拟程序里,甚至不在电路图上的涂鸦中。这些东西都是对真实世界的表征。它们帮助我们理解真实世界是如何运作的。最终,我们所创建和设计的所有电路都会与真实世界发生交互,即使只是一个按钮或一个显示器。因此,我们有必要稍微谈谈一些用于将电路连接到这个庞大而复杂世界的工具。

The real world is the place where you and I live. It isn’t in this book or in a simulation or even the scribbles on a schematic. All those things are representa- tions of the real world. They help us understand how the real world works. At some point, all the circuits we create and design will interface with the real world, even if it is just a button to press or display to look at. It follows that we should talk a bit about some of the things we use to hook our circuits up to the big, bad world.

弥合鸿沟#

BRIDGING THE GAP

如果这本书是在计算机还处于模拟时代写的,那么这一节根本就不需要。然而,现在这些烦人的小数字芯片无处不在,使得这部分内容变得尤为重要。如果你想把你的最新小玩意儿打造成“超炫的数字科技”,你就必须在某个时刻跨越模拟与数字之间的鸿沟。了解一些关于模拟转数字的知识,是个不错的主意。

If this book had been written back when computers were analog, this section wouldn’t even be needed. As it is, the proliferation of those pesky little digital chips gives it top billing. You need to bridge the gap between the analog and the digital at some point if you want to market your latest gadget as“way cool digital technology.” Knowing a bit about how to make the analog-to-digital leap seems like a good idea.

模拟 vs. 数字#

Analog vs. Digital

如果我们把模拟放在拳击台的一角,把数字放在另一角,然后让它们厮杀一番,你觉得谁会赢?在当今世界,数字技术风头正劲,但它到底和模拟技术有何不同?我们来看看。

什么是模拟?它是某个被现代数字工程师遗忘的古老术语吗?并不是。模拟基本上指的是连续变化的信号。这意味着被测量的对象可以在时间上被无限细分。比如,一个信号在1秒内从A变为B。如果你在1秒内观察它,它就会处于A和B之间的某个位置。它是一个连续变量。无论你如何细分时间段,信号中仍然包含信息。

我们感知到的世界本质上是模拟的。颜色从光谱的一端无限渐变到另一端。街上飞驰而过的汽车发出的声音在音量上是连续增强然后减弱的。

开车时,你会根据周围的交通和环境不断调整车速。你周围的世界是模拟的。

那么,数字又是什么呢?“是我的电脑。”你可能会这么说。是的,没错。但让我们从更基础的层面讲讲。举起你手上的一个“digit”(即手指,如果你不知道的话),现在把它放下,再举起来。这就是数字。它要么存在,要么不存在。我不确定“digit”(手指 [1] )是不是“digital”这个词的来源,但它有助于我记住它的含义。因此,数字的最简单形式就是两种状态:要么有,要么没有。

我们再深入一点。如果我们观察手指从完全放下到完全举起的过程呢?仔细看,你会发现数字信号实际上本质上是模拟的。没错。正如我一个工程师朋友常说的那样:“实际上没有真正的数字信号——它们只是长得奇怪的模拟信号。”所以数字只是一个感知方式。你在一个特定的时间窗口内观察某个东西,然后定义它是存在还是不存在。数字是对模拟电平的预设定义。

如果数字其实是伪装成模拟的,那我们干嘛还要用它?早期人们发现数字信号在通信中表现良好。还记得电报吗?它用点/划的数字序列表示字母。为什么它效果好?我们再看一下“数字手指”信号的例子。在远处,观察者很容易判断你的手指是举着还是放下。实际上,这种信号每天都在高速公路上使用!说正经的,重点是:通过使用数字信号进行通信可以避免错误。

那使用数字信号的缺点是什么?电报没持续多久就被模拟通信方式取代了。原因在于带宽,这是衡量信号承载信息量的指标。模拟信号可以承载大量信息。它在给定信号范围内可以具有无限多个电平。

回到手指的例子:如果你有一架好的望远镜,可以从远处聚焦在手指上,就能清楚地看到手指可以表示的不同电平。如果你有一个超大的手指,不用望远镜也可以做到。这说明模拟信号比数字信号更容易表示大量信息。但为此,你需要 更多的能量! [2] (请想象此处有个男人般的咕哝声。)如果你无法从信号中获得更多能量,噪声或其他干扰信息就很容易破坏信号。当你离你最喜欢的广播电台太远时,信号开始变得模糊,这就是这种情况的体现。有时候你可以通过更好的滤波器、放大器等为接收器“提供更多能量”。尽管如此,信号完整性始终是模拟系统面临的挑战之一。

另一方面,要让数字信号传输大量信息,它就必须运行得足够快。过去当人们想听彼此说话时,使用模拟信号更容易。当时的数字技术根本无法足够快地处理音频信息的所有复杂性。因此,多年来,通信主要依赖模拟的信息编码与解码方式。然而,数字在另一个领域悄然崛起——布尔逻辑的应用。 [3]

数字信号可以用来表示布尔语句,一个电平表示真,另一个表示假。计算机就此诞生。诸如“如果这是真的,那就执行那个”的语句可以由机器来执行。布尔逻辑是基于对世界的数字化表示。但别以为只有数字计算机。一段时间内,为了处理大量信息,也曾使用过许多模拟计算机。最终,数字处理速度足够快,取而代之。

If we put analog in one corner of a boxing ring and we put digital in the other corner and then we let them duke it out, who do you think would win? In today’s world, digital is all the rage, but what really sets it apart from analog? Let’s find out.

What is analog? Is it merely some ancient term lost in the world of today’s digital engineers? No, analog basically means a continuously variable signal. It means that the item being measured can be chopped up into infinite little pieces over time. Say, for example, a signal changes from A to B over a 1-second interval. If you look at it before 1 second is over it will be somewhere between A and B. It is a continuous variable. No matter how small you slice up the time segments, there is still a signal with information there.

The world as we perceive it is analog in nature. Colors blend infinitely from one end of the spectrum into the other. The sound as a car races by on the street is heard in a continuously increasing and then decreasing volume level.

As you drive a car, you continuously change speed in response to the traffic and environment around you. The world around you is analog.

So what, then, is digital?“My computer is,” you say. Yes, this is true. But let’s get a little more basic with it. Hold up one of the digits on your hand. (A digit is your finger, in case you were wondering.) Now put it down, now put it up again. This is digital. It is either there, or it is not. I don’t know if digit (as in finger [1]) is where the term digital came from, but it helps me remember what it means. So the simplest form of digital is two states: It’s either there or not.

Let’s go even deeper. What about the time it takes to change state? What if we look at our digital finger as it moves from all the way down to all the way up? If you look at it carefully, you see that a digital signal is really analog in nature. This is true. As one of my engineer friends is fond of saying,“There is no such thing as digital, really—just funny-lookin’ analog.” So digital is really just a mode of perception. You look at something in a specifically determined time frame and define whether it is there or it is not. Digital is a predetermined defi- nition of analog levels.

If digital is really analog in disguise, why even bother with it? Early on it was discovered that digital signals worked well in communication. Remember the telegraph? It used a digital dot/dash series to represent a letter. Why does it work well? Let’s look at our digital finger signal example again. At a distance, it is obvious to the observer whether your finger is up or down. In fact, this sort of signal is used on the freeway every day! All kidding aside, the point is that you can avoid communication errors by using digital signals for communication.

So what is the drawback to using digital signals? The telegraph didn’t last long. It was quickly replaced by analog forms of communication. The reason for this has to do with bandwidth, a measure of the amount of information a signal can carry. The analog signal can carry vast amounts of information. It can, in fact, have an infinite number of levels for a given signal range.

Back to the finger example: If you have a good telescope and can focus in on the finger from far away, you can easily see the varying levels that the finger can represent. The same thing can be accomplished without a telescope if you have a very large finger. This implies that analog signals can represent large amounts of information much more easily than digital signals can. To do this, though, you just need more power! [2] (Imagine a manly grunt here.) If you can’t get more power out of the signal, noise or other unwanted information can easily disrupt the signal. This is what happens when you get too far away from your favorite radio station and it starts to sound fuzzy. Sometimes you can give the receiver“

more power” with better filters, amplifiers, or the like. Nevertheless, signal integrity is one of the struggles with analog systems. On the other hand, to get a digital signal to move a lot of information, it has to work fast. Back when people wanted to hear each other talk, it was much easier to use analog signals. The digital technology of the time simply couldn’t work fast enough to represent all the complexities of the audio information. Thus for many years communication efforts focused on analog encoding and decod- ing of information. However, digital was being used in another domain entirely, in the application of Boolean logic. [3]

Digital signals could be used to represent Boolean statements, one level indi- cating true and the other indicating false. The computer was born. Statements such as,“If this is true, then do that,” could now be executed by machines. Boolean logic is based on a digital representation of the world. Don’t think that there are only digital computers, though. For a while there were many analog computers in use to handle computations involving large amounts of informa- tion. Digital processing speeds eventually increased enough to take over these applications.

我们有了模拟#

So We Have Analog

优点是模拟可以表示大量信息,并且我们周围的世界很容易用模拟信号表示。缺点是无论是发送端还是接收端都需要更多的能量来解析模拟信号,且微弱的模拟信号很容易受到外部干扰。

The upsides are that analog can represent lots of information, and the world around us can easily be represented by analog signals. The downsides are that it takes more power in either the transmitter or receiver to resolve the analog signals, and small analog signals can be easily disrupted by outside influences.

然后是数字#

Then There Is Digital

数字的优点是低功耗传输,以及能够表示逻辑语句。缺点是信息容量有限(带宽低),必须运行得很快才能处理大量信息,且我们周围的世界本质上并非数字。

The pros of digital are low power transmission and the ability to represent logic statements. The cons are information limits (low bandwidth), requiring it to work fast to process large pieces of information, and the fact that the world around us is analog, not digital in nature.

两者兼得的美好愿景#

The Best of Both Worlds

如果我们能两者兼得,不是很好吗?工程师们也是这么想的,于是他们发明了几个缩略词来启动这个过程:ADC(模数转换器)和DAC(数模转换器)。让我们来看看它们是什么。

Wouldn’t it be great to have the best of both worlds? That’s what engineers thought, so they coined a couple of acronyms to get the process started: ADC (the analog-to-digital converter) and DAC (the digital-to-analog converter). Let’s find out what these are.

模数转换与反向操作#

A-TO-D AND BACK AGAIN

什么是模数转换(ADC)?是一种宗教体验吗?是数模转换(DAC)的反义词吗?模数转换就是把真实世界转换成0和1,以便数字技术能够处理它。可以合理地说,数模转换就是这个过程的逆转。在这里我们将探讨模数到数模的转换到底是什么,以及它的用途。

What is A-to-D conversion (or ADC)? Is it a religious experience? Is it the oppo- site of D-to-A conversion (or DAC)? A to D is all about taking the real world and making it into ones and zeros so that digital technology can manipulate it. You can reasonably say that D to A reverses the process. Here we will explore what this A to D to A is and what it is good for.

A 代表模拟#

A Is for Analog

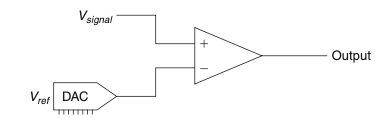

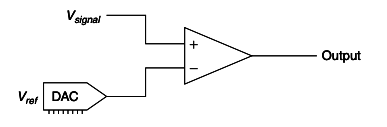

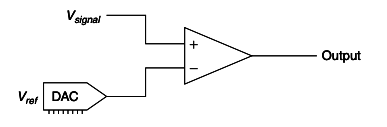

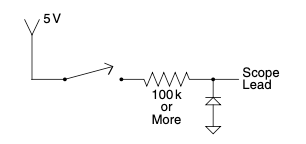

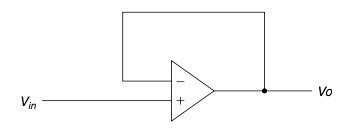

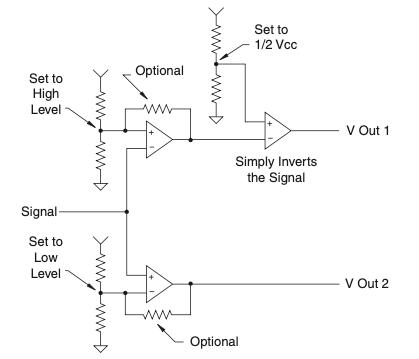

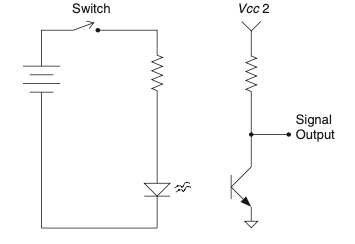

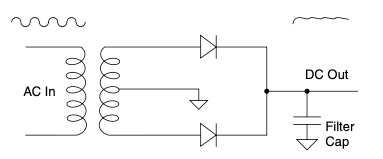

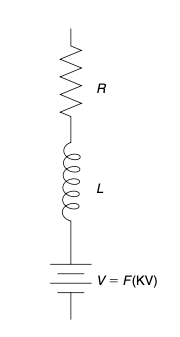

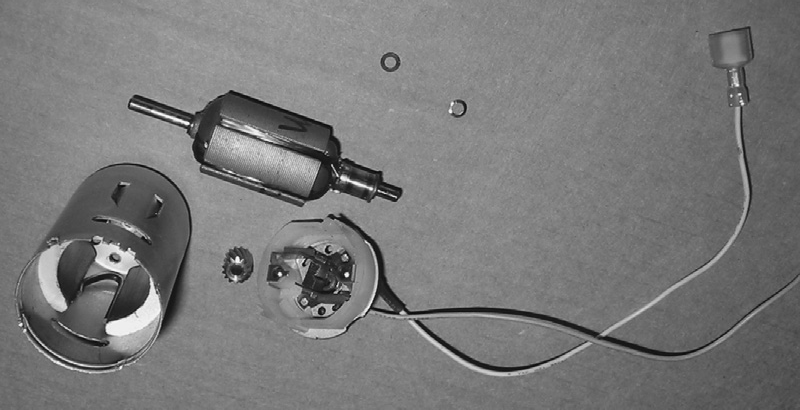

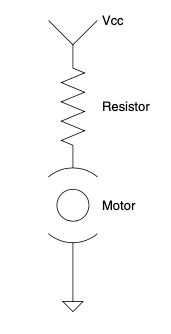

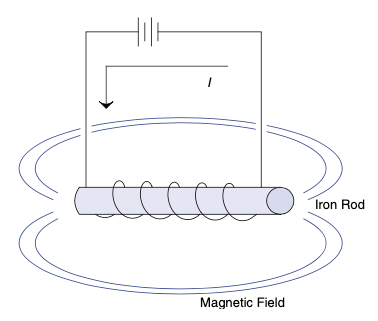

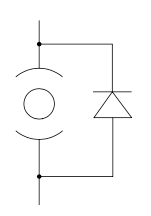

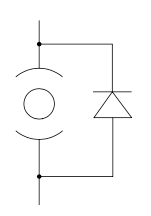

模拟信号通过在预定的时间间隔内将其切分成若干段来转换为数字信号。(这种切分称为采样率。采样率越快,可数字化的频率就越高。)然后在该时间点测量信号,并赋予一个数字值,这个过程称为对信号采样。数字信号(通常用1或0表示)可以组合在一起以表示不同的模拟电平。一个数字可以表示两个电平。如果使用二进制数系统,使用更多的位数可以表示更多的电平。电平的数量是2的位数次幂。四位可以表示16个电平(2^4)。八位可以表示256个电平(2^8),依此类推。一种常见的确定信号电平的方法是使用比较器,如 图 4.1 所示。

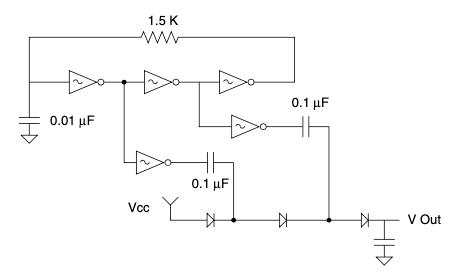

图 4.1 比较器驱动的 ADC。#

研究这个应用。在这个例子中,信号与参考电压进行比较。你从最小值开始逐步增加参考电压到最大值。当信号大于参考电压时,运算放大器比较器将输出高电平,即1。当参考电压更大时,输出为低电平,即0。如果电路知道输出改变状态时的 \(V_{ref}\) 的值,那么此时 \(V_{ref}\) 大约等于 \(V_{signal}\)。我说“大约”是因为总会存在分辨率的问题。如需了解更多内容,请继续阅读。

An analog signal is converted to digital by chopping it up into chunks at prede- termined time intervals. (This chopping is called the sample rate. The faster the sample rate, the higher the frequency that can be digitized.) Then the signal is measured at that point in time and assigned a digital value, which is called sampling the signal. Digital signals (typically represented as 1 or 0) can be crammed together to indicate different levels of analog. A single digit can indicate two levels. If you use a binary numbering system, you get more levels by using more digits. The number of levels goes up by 2 raised to the power of the number of digits. Four digits give you 16 levels (2^4). Eight digits gives you 256 levels (2^8) and so on. One common way of determining the level of a signal is to use a comparator, as shown in Figure 4.1.

FIGURE 4.1 Comparator-driven ADC.#

Study this application. In this case, the signal is compared to a reference voltage. You increase the reference voltage from min to max. When the signal is larger than the reference voltage, the op-amp comparator will output a high, or a 1. When the reference voltage is the larger of the two, the output will be low, or a 0. If the circuit knows the value of \(V_{ref}\) at the time the output changes state, this is when \(V_{ref}\) is approximately equal to \(V_{signal}\). I say approximately because there is always a question of resolution. For more on this topic, read on.

D 代表数字#

D Is for Digital

现在我们有了数字信号,我们可以用它做很多有趣的事情。我们可以传输它、接收它、操作它,而不用太担心信号的丢失。但接下来是什么?比如我们将吉他音乐转换为数字格式,以加入一些酷炫的音效。你不能仅仅把这些数字数据直接输出让人听见。它必须被转换回模拟信号。为什么?因为我们对某些事物在模拟格式下的感知更敏锐。如果你不相信我,看看你车上的速度表;我敢打赌它是个模拟表盘。(有些东西我们喜欢用数字方式看,但那通常是为了避免处理无限的增量;看看你车上的里程表就是个例子。[4])

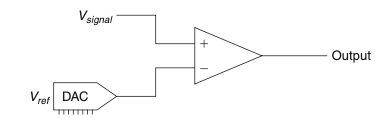

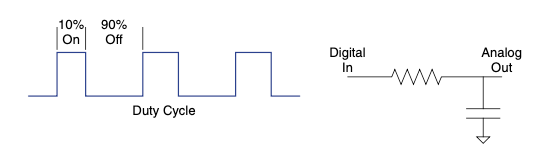

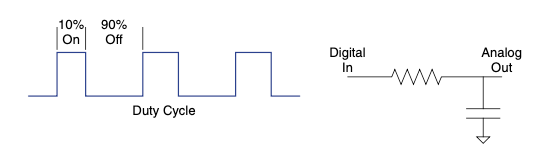

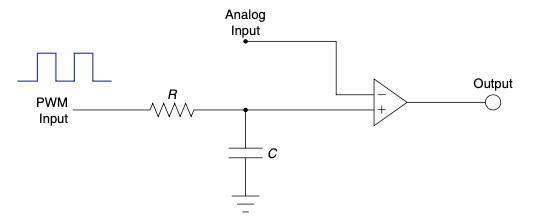

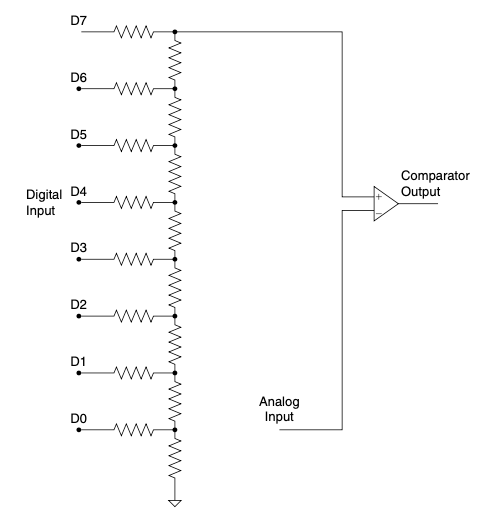

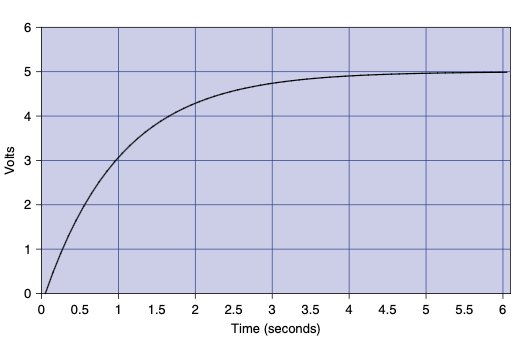

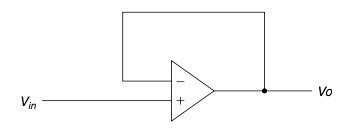

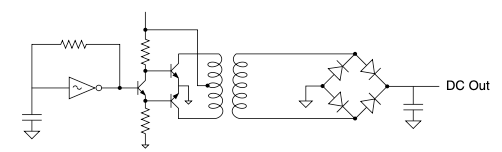

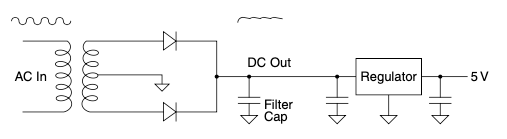

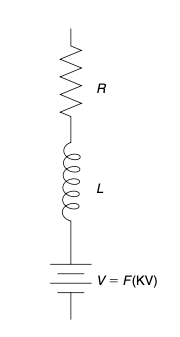

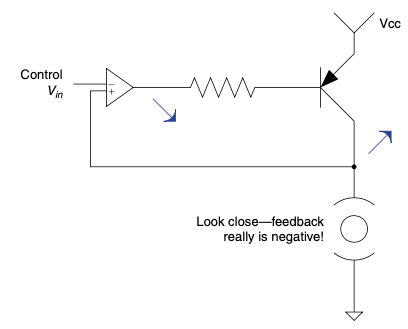

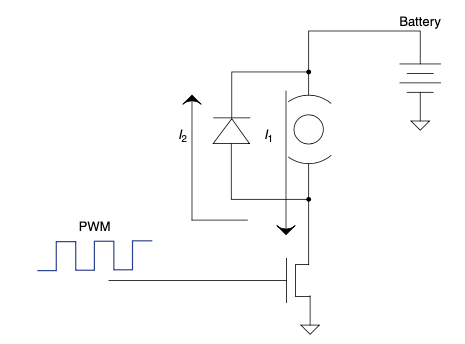

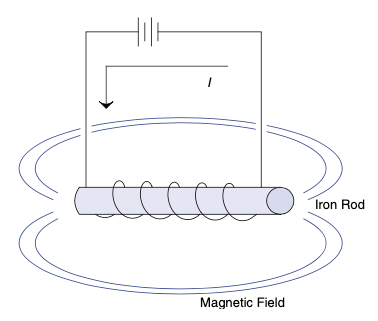

为了将数字信号转换回模拟信号,电路必须模拟它所代表的模拟信号。这总是需要某种滤波过程。有很多方法可以实现数模转换。我最喜欢的方法之一是脉宽调制(PWM)。在PWM电路中,设备的输出以一定频率开关——参见 图 4.2。其开启与关闭所占的时间百分比,就是它所代表的模拟信号大小。这个百分比称为占空比。

图 4.2 通过占空比控制的模拟输出。#

数字PWM信号输入到一个低通滤波器中,该滤波器会去除信号的开关频率,最终留下一个模拟信号。这个信号可以表示的电平数量取决于PWM信号的分辨率。即PWM在不同占空比下开关的能力。例如,一个能以5%占空比增量切换的PWM,其分辨率就比一个能以1%增量切换的电路低——参见 图 4.2。这意味着数字信号只能表示模拟信号的离散电平。这些电平构成了信号的分辨率。

为什么分辨率如此重要?我们在比较器示例中提到,电路知道 \(V_{ref}\) 是什么电平。它是怎么知道的?它必须以某种方式生成该值。这是通过某种数模转换(DAC)过程实现的。而DAC过程的分辨率将决定ADC过程的分辨率。

所以我们就这样,从模拟到数字,再回到模拟。这真的是一个循环。让我们来看一些例子,看看这个概念是如何运作的。

这让我思考了一下。人类是否天生喜欢用模拟格式来显示瞬时信号参考,而倾向用数字格式来呈现累计信息?也许某位聪明的学生可以把这个问题作为论文课题研究,这样我就不用费脑子想这个了。如果你真的做了,记得给我寄一份结果;我很想知道答案!

That makes me think a bit. Is it human nature to prefer instantaneous signal references to be displayed in analog format whereas cumulative information is preferred in a digital format? Maybe some bright student out there will make this a thesis project so I don’t have to think so hard about it. If you do, make sure you send me a copy; I’d love to know the results!

Now that we have a digital signal we can do lots of fun things with it. We can trans- mit it, receive it, and manipulate it without worrying much about signal loss. But what is next? Say we convert guitar music into digital format to add some neat sound effects. You can’t simply send the digital data back out to be heard. It must be converted back to analog. Why? Because there are certain things we perceive well in an analog format. If you don’t believe me, take a look at the speedometer in your car; I’ll bet it is an analog gauge. (There are some things we like to see digitally, but usually that’s so we don’t have to deal with infinite increments; look at the odometer in your car for this example. [4])

To convert a digital signal back to analog, the circuit has to simulate the ana- log signal it represents. This always requires some kind of filtering. There are many ways to convert digital to analog. One of my favorites is by pulse width modulation (PWM). In a PWM circuit, the device’s output switches on and off at a given frequency—see Figure 4.2. The percentage of time it is on versus off is the amount of analog signal it represents. This percentage is called the duty cycle.

FIGURE 4.2 Duty cycle-controlled analog output.#

The digital PWM is fed into a low-pass filter that removes the switching fre- quency of the signal, essentially leaving an analog signal. The number of levels that this signal can represent depends on the resolution of the PWM signal. This is the capability of the PWM to be switched on and off at varying duty cycles. For example, a PWM that could switch on and off in increments of 5% duty cycle would have less resolution than a circuit that can handle increments of 1% duty cycle—see Figure 4.2. This means that digital signals can repre- sent only discrete levels of analog signal. These levels are the resolution of the signal.

Why is resolution so important? We stated earlier in the comparator example that the circuit knows what level Vref is at. How does it know that? It must generate it somehow. It does so with some type of DAC process. It is the resolution of that DAC process that will determine the resolution of the ADC process.

So there we are. We went from analog to digital and right back to analog again. It really is a circle. Let’s look at some examples to see this concept in action.

要进行一点数模转换,才能完成一次模数转换#

IT TAKES A LITTLE D TO A TO GET A LITTLE A TO D

不久前,我在向一位工程师朋友解释我关于“世界本质上是模拟的”的观点。他发来如下回应邮件:

我想对你关于“我们感知的世界是模拟的”这一说法提出反驳。我认为,自然界中的数字感知和模拟感知一样多,甚至更多。比如:生或死、黑夜或白昼、开或关、湿或干、植物或动物、主导或服从、捕食者或猎物、饥或饱、粗糙或光滑、冷或热、模糊或清晰、单一或多样、伪装或警告、平原或山地、森林或沙漠、风暴或晴朗、噪音或寂静、失明或视力、男性或女性、丰年或饥荒、生存或死亡、开启或关闭,等等。当然,像温暖、微风、日落和杂食这类感知也存在,但总体来说,我认为我们的自然感知更偏向数字。[5]

从很多方面来说,他在这段优雅评论中说得是对的;但他所说的是我们的感知。我们把来自世界的模拟信息划分到“数字桶”中。(当然,比如冷热之间确实存在中间状态。)我认为我们之所以这么做,是为了便于决策、减少信息存储量,并简化交流。我们在合适的时候施加数字化的感知。也许我更好的说法是:“世界本质上是模拟的,而我们赋予其数字化的感知。”有了这个前提,让我们继续深入模数转换的一些基础机制。我们从前几页讲到的 DAC 和简单比较器开始。

一个简单的比较器会根据一个输入是否高于或低于另一个输入输出高电平或低电平(参见 图 4.3)。这是使用比较器的绝佳时机,因为数字电路喜欢明确的高低电平信号。我们来看看这个电路的基本过程:你将一个数字值转换为一个已知的模拟电平,与一个模拟信号进行比较,如果它们非常接近(这时分辨率就很关键),那么你输出的数字值就代表了该模拟信号的数值。

图 4.3 比较器驱动的 ADC。#

引用自我的一位好友 Michael Angeli。我一直很喜欢他的写作风格;也许哪天我能拉他一起合作点什么。

This quote is from a good friend of mine by the name of Michael Angeli. I’ve always liked his writing style; maybe someday I can get him to collaborate on something with me.

我们来看一个例子。你正在转换一个实际值为 4.45 的模拟信号。你试着用 DAC 输出 1,比较器说“更高”(它通过输出 1 或高电平来表示 [6] )。你接着输出 2,比较器还是说“更高”。然后你输出 3,再输出 4。猜猜每次比较器怎么说?没错,它每次都说“更高”。那接下来你试什么?当然是输出 5。这时比较器说“更低”。现在你的电路知道信号值在 4 和 5 之间。此时你从这两个值中选一个 [7] (假设 DAC 在 0–5 的范围内只输出六个离散电平)。DAC 的步进越小,就能越精确地估算模拟信号的值。步进越小,信号的分辨率就越高。

还有一种比简单遍历所有可能值更好也更快的方法。(现在我们增加 DAC 的分辨率来说明这个问题。)首先将 DAC 的第一次输出设为整个范围的一半。这种情况下你输出 2.5。观察比较器的输出并进行逻辑决策(数字信号在这方面表现很好)。你可以看出比较器是否输出“更高”,从而排除掉 2.5 以下的所有值。接着你输出剩余范围的一半——也就是 3.75。再次观察比较器输出并排除更多不可能值(高电平表示排除其以下所有值,低电平则排除其以上所有值),然后再输出剩余范围的一半。重复这个过程,直到达到分辨率极限为止,你就能得出该模拟信号的近似值。这种快速模数转换方法叫做逐次逼近,常用于需要高速 A/D 转换的场景。

你是否注意到,在讲解模数转换过程时我经常使用“近似”这个词?这是因为数字信号永远无法真正等同于模拟信号;它总得在某处“画一条线”。别忘了数字意味着存在离散步进。模拟,按照定义,是具有无限增量的。既然你已掌握 A/D 转换的基本原理,我们再来看几个 DAC 电路的例子,以便更直观地理解。[8]

记住,比较器的具体电压输出并不重要。此时电路只关心信号的“状态”。是高还是低,是 1 还是 0,是真还是假?数字信号只有这两种状态。

Remember that the specific voltage output of the comparator isn’t important. At this point in the circuit you only care about the“state” of the signal. Is it high or low, 1 or 0, true or false? You get only those two options in a digital signal.

需要注意的是,你并不知道实际信号更接近哪个值。你只需选择其中一个。这是一个完全主观的决定,也是数字处理的基本特征。这也正是分辨率如此重要的原因——它缩小了误差范围。

It is important to note that you do not know to which value the actual signal is closer. You simply need to pick one. It really is an arbitrary decision and is fundamental to digital processing. This is the reason that resolution is so important. It narrows the gap and thus the lack of exact knowledge of the signal.

越来越多的 DAC 和 ADC 电路已被集成在你所使用的器件中。你可能只是发出一个命令:“采集那个信号样本。”但如果你想知道为什么器件没按预期工作,理解其内部原理是非常重要的。

More and more often these different types of DAC and ADC circuits are built into whatever part you are using. You might process a command that says,“Get me a sample of that signal.” However, it is important to have an idea of what is going on in these parts if you want to be able to figure out why it isn’t working the way you expected it to.

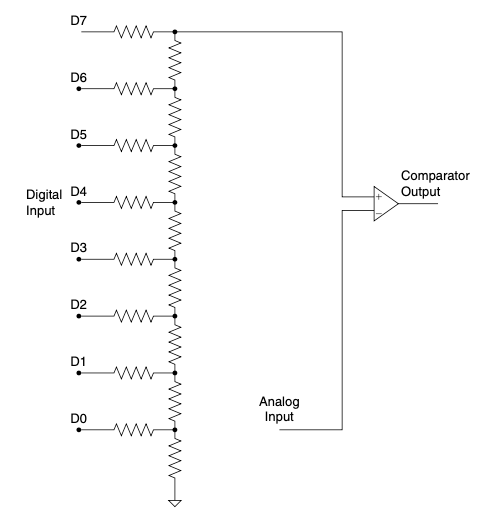

图 4.4 R2R 电阻梯。#

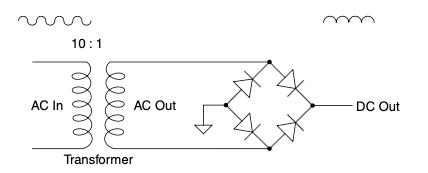

这是实现数字电压输出的一种巧妙方法,你可以将 R2R 电阻梯封装在一个紧凑模块中,如 图 4.4 所示。注意不要在没有缓冲的情况下将其接到低阻抗设备上,否则其输出电平会受到外部负载的影响。

这个电阻梯是如何工作的?一个数字字节被输出到电阻梯上,电阻梯将电压电平转换为比较器的输入电压。需要注意的是,最高有效位(MSB)对输出影响最大,最低有效位(LSB)影响最小。这种方式非常适合前文所述的逼近法。你只需将想要的 DAC 值加载到电阻上,然后观察输出信号即可。这种方式非常快。最大的问题是它需要很多输出引脚。(这些引脚必须能够吸收或提供足够电流才能正常工作。)有一点要注意:确保你的处理器能承受电阻梯的负载。我多年前在某个电路应用中使用的 Zilog 处理器表现良好,甚至还有板载比较器用于 ADC 过程,但我用了所有的引脚,几乎没有剩余信号引脚可用。

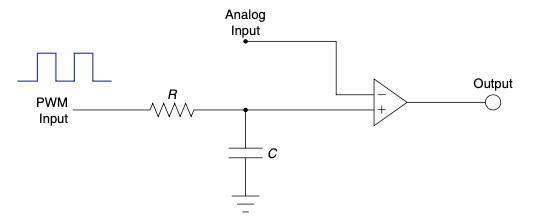

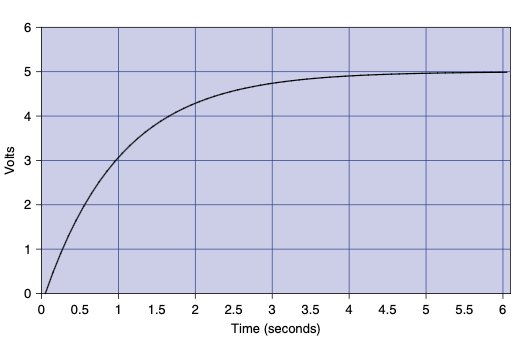

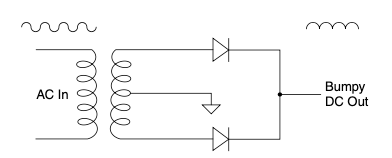

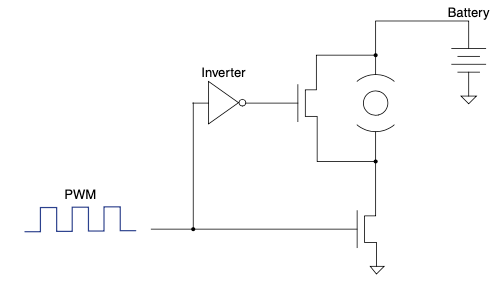

在这个电路中,PWM 信号的占空比从 0% 开始逐渐升高,直到超过模拟信号值,比较器就会指示变化——参见 图 4.5。模拟电压由 PWM 信号发生状态变化时的占空比来表示。RC 滤波器必须将 PWM 信号转换为基本的模拟电平。这意味着 PWM 的开关速度必须远远快于你所要数字化的信号的变化速度。

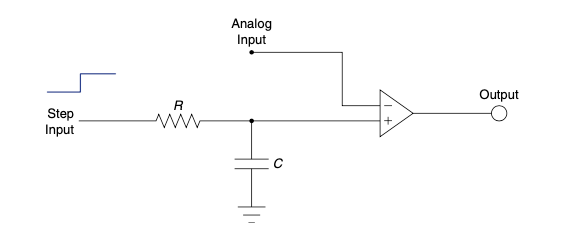

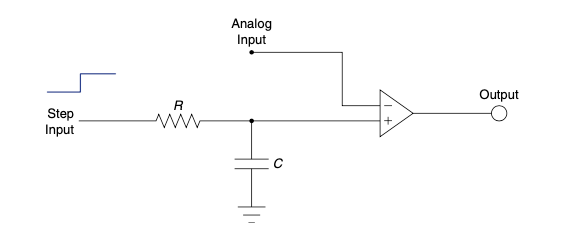

这种方法依赖于基本 RC 电路的瞬态响应(参见 图 4.6)。阶跃输入使比较器的输入根据 RC 电路的响应时间增加。RC 电路的输出等于

\(Vi(1 - e^{-(t/\tau)})\)。因此,如果你知道时间常数 tau(即 R * C),就可以根据时间计算电压。在某些微控制器中,这种计算可能比较繁琐,但很多时候并不需要很高精度,可以使用一个查找表来实现。在许多情况下,还会为该电路增加一个低电阻放电路径,以确保 RC 电路的输出从零开始。

图 4.5 PWM 斜坡。#

图 4.6 RC 充电时间。#

这个电路的缺点是需要进行曲线计算,但信号的前三个时间常数是相当线性的近似。根据具体应用,这可能就足够了。(回顾第一章开头关于电子学与手榴弹的类比,看看什么时候“够用就行”。)如果你的任务要求不高,也不接近电压上限轨,就可以简单地计时而跳过那些复杂的计算,从而使这成为一种快速、廉价、实用的 ADC。

以上就是三种获取模拟信号数字近似值的简便方法。这些电路都可以单独作为 DAC 使用。

最后一点:如今微控制器越来越普遍地内置了 A/D 转换器。然而,它们几乎都基于使用 DAC 实现 ADC 的原理。学习本节内容可以帮助你了解这些器件内部究竟是怎么工作的。你对内部原理了解得越多,你就会成为更出色的工程师!

A while ago I was explaining my thoughts on the world being analog in nature to a fellow engineer. He emailed me the following response:

I would like to provide counterpoint to your assertion that“the world as we perceive it is analog in nature.” I think that there are as many, if not more, natural digital perceptions as there are analog. Some samples: alive or dead, night or day, open or closed, wet or dry, flora or fauna, dominant or submissive, predator or prey, hungry or full, coarse or smooth, hot or cold, fuzzy or sharp, open or closed, single or multi, camouflage or warning, flat or mountainous, forest or desert, stormy or clear, noise or silence, blind or seeing, male or female, feast or famine, survive or die, on or off and so on. Granted, things like warm, breezy, sunsets, and omnivorous are there, but for the most part, I think our nature perceptions are digital. [5]

In many ways he is correct in his eloquent comments; however, he refers to our perception. We place the analog information from the world into“digital buckets.” (There are certainly levels between hot and cold, for example.) I think the reason we do this is to facilitate decision making, to limit the store of infor- mation, and to ease communication. We impose a digital perception when it makes sense to do so. A better phrase I could have used is something like, “The world is analog in nature, upon which we impose our digital perceptions.” With that in mind, let’s look at some more of the nuts and bolts of A-to-D conver- sion. We’ll start with the DAC and a simple comparator from a couple of pages back.

A simple comparator will output a high or low signal depending on whether one input was above or below the other (Figure 4.3). This is a great time to use a comparator, since digital circuits like obvious signals such as high and low. Let’s drill the basic process of this circuit: You convert a digital number to a known analog level, compare that to an analog signal, and if it is close to the same value (here is where resolution counts), the digital number you output represents the analog value.

FIGURE 4.3 Comparator-driven ADC.#

Let’s do an example. You are converting an analog signal with the actual value of 4.45. You try outputting a 1 on your DAC. The comparator says“higher” (it does this by outputting a 1, or a high signal [6] ). You then try outputting a 2. The comparator says“higher.” Now you try a 3, then a 4. Guess what the com- parator says each time. That’s right, it says“higher.” So what do you try next? Of course, you try a 5. Then the comparator says“lower.” Now your circuit knows that the value is between 4 and 5. At this point you pick one of these two values [7] (assuming in this case that the DAC only outputs six discrete levels over a range from 0–5). The smaller the steps or increments that you can output with the DAC, the closer you can estimate the value of the analog signal. When you make the steps in the DAC smaller you increase the resolution of the signal.

There is a better and faster way than merely sweeping across all the values in the range. (We will increase the resolution of our DAC now to illustrate this point.) Start by making your first output on the DAC equal to ½ of the entire range. In this case you output 2.5 on the DAC. Now look at what the comparator says and make a logic decision (digital is good for this sort of thing). You can see whether the comparator says“higher,” and you can eliminate everything below 2.5. So you make your next output equal to half of the remaining range—in this case, you output 3.75. Look at the comparator again and eliminate some more possibilities (a high eliminates everything below the number, whereas a low eliminates everything above the number), then output half the remaining range. Repeat this process until you are out of resolution and you will have an approximation of the analog signal. This is a very fast way of converting an analog signal known as successive approximation. It is often used when high- speed analog-to-digital conversion is needed.

Did you notice that I often use the word approximation as the A-to-D process takes place? This is because a digital signal can never truly equal an analog signal; it must always draw the line somewhere. Do not forget that digital means that there are discrete steps involved. Analog has, by definition, infinite increments. Now that you have the basic idea behind the A-to-D conversion process, let’s look at some examples of DAC circuits to develop a more intuitive understanding. [8]

FIGURE 4.4 The R2R ladder.#

This is a slick way to get a digital voltage level, and you can get the R2R ladder in a nice compact package, as shown in Figure 4.4. You must take care not to hook it up to any low-impedance devices without buffering, since its output level can be easily affected by external loads.

How does the ladder work? A digital byte is output to the ladder, which changes the voltage level to the input of the comparator. You should note that the MSB (most significant bit) has the most effect on the output. The LSB (least significant bit) affects the output the least. This works very well with the approximation method described earlier. You simply load the DAC value you want on the resistors and look at the output signal. It is very fast. The biggest downside is that it uses a lot of output pins. (The output pins must be able to sink or source sufficient current to work correctly.) One caution: Make sure your processor can handle the output load of the ladder. The Zilog processor I used in one application of this circuit years ago worked fine and even had an onboard comparator for the ADC process, but I did use every pin, leaving little room for additional signals if needed.

In this circuit, the duty cycle of the PWM signal is ramped up from 0% until it passes the value of the analog signal, as indicated by the comparator—see Figure 4.5. The analog voltage is represented by the percentage of the PWM signal when the comparator changes state. The RC filter must turn the PWM into basically an analog level. This means that the PWM must switch significantly faster than the speed of the signal you are trying to digitize.

This method relies on the transient response of the basic RC circuit (Figure 4.6).

The step input causes the input to the comparator to increase according to the

response time of the RC circuit. The output of the RC circuit is equal to

\(Vi(1 - e^{-(t/\tau)})\). So if you know the value of tau, which is R * C, you can calculate

the voltage based on the time it takes to pass the input. This can be tedious to

calculate in some micros, but often high accuracy is not needed and a lookup

table of the values can be implemented. In many cases, a lower-resistance discharge path is added to this circuit to ensure that the output of the RC circuit begins at zero.

FIGURE 4.5 PWM ramp.#

FIGURE 4.6 RC charge time.#

The downsides to this circuit are the curve calculations, but the first three tau of the signal are a fairly linear approximation. Depending on the application, that might be good enough. (Review the connection between electronics and hand grenades way back at the beginning of Chapter 1 to see when things are“good enough.”) If your task isn’t too demanding and you don’t get too close to the upper rail, you can simply count time and toss out that complex calculation, making this a quick, cheap, and dirty ADC.

So there you have three easy ways to get a digital approximation of an analog signal. All these circuits are perfectly fine to use as DACs only. One last thought: These days a built-in A/D converter is an increasingly com- mon feature on a microcontroller. However, they nearly all work on the princi- ple of using a DAC to make an ADC. Studying this section can help you to get an idea of what is really going on in there. The more you know about how it works on the inside, the better engineer you will be!

数字信号处理#

Digital Signal Processing

DSP,即 数字信号处理,指的是对从模拟信号数字化后的数据进行操作。在很多情况下,如音频和视频,信号在经过 DSP 处理后还会被转换回模拟信号。关于 DSP 的书籍有很多,比本书对该主题的覆盖更为深入。然而,在这里我只希望对这个话题提供一点基本理解。

DSP 的优势之一是可以即时更改滤波器的参数。这使得工程师能够创造出各种新颖的信号处理解决方案,这些在传统的模拟设计中很难实现。通常,DSP 解决方案的成本也高于模拟方案,因此要确保你确实需要它。不要在本来用一个 25 美分的运算放大器就能完成任务的地方,硬是塞一个 5 美元的 DSP 芯片进去。这并不是说 DSP 没有用武之地。没有 DSP,我们就不会有 MP3、WMA、AC3、AAC、MP4、WiFi,以及一大堆可以炫耀的缩写!说起来,DSP 技术可能比其他任何技术都“制造”出更多缩写词!

DSP, or digital signal processing, refers to manipulating data that is digitized from an analog signal. In many cases, such as audio and video, the signal is converted back to analog after DSP occurs. Many books on DSP are available that offer far better coverage of this subject than this one. However, here I only hope to create a bit of understanding on this topic.

One of the advantages of a DSP is the ability to change parameters of the filters on the fly. This allows engineers to create all sorts of new solutions to processing signals that are very difficult to achieve with comparable analog designs. Typically, a DSP solution is also more expensive than an analog one, so be sure you really need it. Don’t slap a five-dollar DSP chip in the circuit when a 25-cent op-amp will do the job. That is not to say DSP doesn’t have its place. Without DSP, we wouldn’t have MP3, WMA, AC3, AAC, MP4, WiFi, and a whole other slew of acronyms to spout about! Come to think of it, DSP technology might be responsible for more acronyms than any other!

拇指法则(Thumb Rules)

模拟信号是连续可变的信号。

数字信号是对特定模拟电平的预定义。

数字信号具有离散的步进。

分辨率是离散步进之间的间距。

DAC 经常被用于 ADC。

Analog is a continuously variable signal.

Digital is a predetermined definition of a specific analog level.

Digital signals have discrete steps.

Resolution is the distance between the discrete steps.

DAC is often used for ADC.

当器件不够理想时#

WHEN PARTS AREN’T PERFECT

在我们讨论器件可能出现的问题之前,需要引入等效电路的概念。它其实很简单:要构建一个等效电路,就是用理想器件的组合来表示一个元件的所有特性和缺陷。

这么做有两个好处:首先,最显而易见的好处是可以对器件的非理想效应进行建模;其次,对 Darren 世界来说更重要的是,通过看到一个真实元件由哪些理想器件组合而成,你可以更容易地将对理想器件的基本理解应用于对真实器件行为的把握。

Before we get into the problems that parts can have, we need to introduce the concept of an equivalent circuit. It is pretty simple: To create an equivalent circuit, you represent all its idiosyncrasies with combinations of perfect components.

This is good for two reasons: First and most obvious, it makes it possible to model the effects of the imperfections. Second, and most important in the World of Darren, is that seeing the combinations of the parts that make up a real com- ponent makes it easier for you to apply the basic understanding of the perfect parts to grasp what the real part is doing.

一切皆无处不在#

Everything Is Everywhere

三种基本电学元件就像海滩上的沙子,它们无处不在。某种程度上,它们甚至比你凉鞋里的沙子还“猖獗”,因为一个元件的效应可能在另一个元件中也能被发现。正是这个事实,造成了电路的实际行为与计算公式预测行为之间最常见的误差之一。这也是为什么数据手册如此重要——即便是描述最基本元件的手册也不例外。数据手册会对元件进行特性说明,描述这些误差来源。

大多数教科书将这些效应称为 误差源,因为它们造成了理想器件与实际器件之间的差异。每个元件中还有其他类型的误差源,后面我们还会讨论其中一些。但那些烦人的 R、L 和 C 的某种组合几乎存在于任何地方。(我希望现在你已经越来越清楚为什么我们一开始要反复强调这三个基本元件。现在正是你恍然大悟的时刻,对自己说:“我终于明白为什么要把这些基本元件烂熟于心了!”)

当你在查找误差源时,最通用的指导原则是问自己:“这个误差源足以解释我所观察到的效应吗?”我们以二极管为例。一个反向偏置的二极管会表现出一点电容,通常在皮法级别。

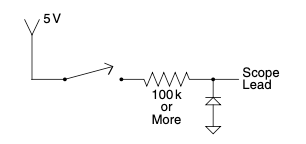

考虑如 图 4.7 所示的电路。如果你将示波器探头连接到输出端,并翻转开关,你会看到如 图 4.8 所示的波形。由于该二极管存在电容,在这种情况下你会预期看到一个 RC 曲线。但这真的是该二极管的误差源导致的吗?还是另有原因?

图 4.7 用于检查的电路。#

图 4.8 你在示波器上看到的 RC 曲线。#

这时就该查阅数据手册了;你查看所用二极管的规格,发现其典型电容是 100 皮法。将这个值代入 RC 电路的响应时间公式:

你得到的时间常数是 10 微秒。再看看示波器,这次你注意到这条曲线达到约 63% 的时间,记住那大概是一倍时间常数(tau)时的幅度。作为一名敏锐的示波器使用者,你使用光标工具测量出信号达到最终值一半所需的时间约为 1 秒。你应该对自己说:“这不对劲。如果是二极管引起的,它的响应应该快得多。”

这个故事的寓意是:要预期每个元件都带有一定量的三种基本元件特性,但也要了解它们的量级,这样你才能判断它是否造成了你所观察到的效应。

The basic three electrical components are like sand at the beach. They get into everything. In a way they are more prolific than sand in your sandals since the effect of one basic component can be found in another. This fact is one of the most common causes of error you will have between the way the equa- tion predicts a circuit will work and the way it actually operates. Chalk this up as one of the reasons datasheets are so important, even the ones that describe the most basic components. Datasheets will characterize the components, describing these error sources.

Most texts call these effects error sources since they are what makes the difference between a perfect or ideal component and what you actually have to work with. There are other types of error sources in every component, and we will discuss a few of them later on, but those pesky R, L, and C in some combination or another are pretty much everywhere. (I hope the reason for drilling the basics of these components is becoming more and more clear. It is appropriate to experience an“a-ha!” moment right now and say to yourself,“Now I see why I need to know those basic parts by heart!”)

The most general guideline to follow when you are looking for error sources is to ask yourself the following: Is this error source enough to account for the effect I am seeing?” Let’s consider a diode as an example for a moment. A diode has a bit of capacitance when it is reverse-biased, typically in the picofarad range.

Consider the circuit shown in Figure 4.7. If you hook your scope lead to the output, and flip the switch, you see what’s shown in Figure 4.8. Since there is capacitance in this diode, an RC curve is what you would expect to see in a situation like this, but is it really due to the error source in this diode or is it caused by something else?

FIGURE 4.7 Circuit to examine.#

FIGURE 4.8 RC curve seen on your scope.#

Here is where the datasheet comes in; looking at the specs on the diode you are using, you find out that this capacitance is typically 100 pf. Plug that into the equation for the response time of an RC circuit:

The number that pops out is 10 μS. Taking a look at the scope again, you now pay attention to the time it takes for this curve to get to about 63%, remembering that is about how far this curve gets in one time constant, or tau. Being such an astute scope operator, you use the cursors on your tool and you measure a time of about 1 second for the signal to get a little over halfway to its final value.“That doesn’t make sense,” you should be saying to yourself,“If the diode is responsible, it would have to be much faster.”

The moral of the story is to expect every component to have some amount of the basic three, but understand the magnitude so you can decide if it is causing the effect you are seeing.

误差源:理想 vs. 现实#

Error Sources, Ideal vs. Real

在你设计的任何电路中,都会存在误差源——例如不够完美的地方、稍有偏差的传感器、不完全符合规范的元件,或是各种各样的问题。

你该怎么处理它们?如果这些误差源不会引发任何问题,那就什么也不用做。例如,如果你有足够的电源,一个漏电容可能根本无关紧要。然而,如果电路是由电池供电的,你可能就会面临麻烦。首先也是最重要的,是要确定该误差源是否真的是个问题,然后再考虑如何解决它。

一旦你认定某个特定的误差源确实是问题,可以通过以下三种方式应对:

换一个更好的元件。堵住一个漏电容的“漏洞”是很难的;[9] 它可不像那个把手指堵在堤坝上的男孩——你没法把手指插进去就把问题解决了。有时候你唯一的选择就是换个元件。例如你可以选用钽电容代替电解电容。但要注意,更好的元件通常也更贵,所以要明智地花钱,而不是随意乱花。不过也要指出,这是解决问题最快的方法,因为不用更改电路设计。

用另一个元件强化薄弱环节。比如,电解电容的频率响应问题可以通过并联一个较小的电容来解决,这个小电容在高频下没有问题。(你可能已经注意到,稳压器的参考设计就是这么做的,以保证输出稳定。现在你知道为什么了。)

通过设计排除误差。这种方式需要最多的工程努力,因为目标是改变电路设计,使误差变得不再重要。众所周知的运算放大器就是这类努力的一个例子。[10] 既然我们已经了解如何应对误差问题,接下来来看看一些常见元件和典型的误差来源。这部分内容是基于个人经验的概述,不能替代用数据手册来治失眠的那种详细程度。

电容中一个非常常见的误差来源是直流电流流过。记住,理想电容会完全阻断直流信号。你可以将它想象成一个与理想电容并联的大电阻。这种情况足够常见,以至于有了自己的行话:如果这种电流流动很明显,那么这个电容就被称为“漏电”,因为直流电流似乎从中“漏”了出来。

A very common source of error in a capacitor is a DC current flow. Remember, the ideal cap will block all DC signals. You can think of it as a large resistor in parallel with a perfect cap. It is common enough to have acquired its own slang term: If this current flow is significant, the cap is said to be leaky, because DC current seems to leak through it.

运算放大器的整个设计初衷就是为了消除晶体管放大器设计中的误差源。这是个非常酷的想法,但确实花了不少功夫!

The whole point of the op-amp was to eliminate error sources in designing transistor amplifiers. It was a pretty cool idea, but it did take some real work!

In any circuit you design, there will be sources of error—things that simply aren’t perfect, sensors that are off a little, parts that aren’t quite to spec, or any myriad of problems.

What do you do about it? Nothing, if the error source isn’t causing you any problems. For example, a leaky cap might not really matter if you have plenty of power available. However, if the circuit is running on batteries you could have a problem on your hands. First and most important, determine whether the source of error is an issue or not before you go about trying to solve it.

Once you figure you have a problem on your hands with a particular source of error, there are three ways to deal with it:

Get a better component. It’s tough to plug the hole in a leaky cap; [9] it isn’t like the boy at the dike—you can’t put your finger in the hole and stop the leak. Sometimes your only choice is another component. In this case you might specify a tantalum cap instead of an electrolytic. Consider, however, that often the better component costs more, so spend wisely, not indiscriminately. Do note, however, that this is usually the quickest way to solve the problem since the design doesn’t have to change.

Shore up the weak component with another component. For example, the frequency response problems with electrolytic caps can be dealt with by adding another cap in parallel, a smaller one that has no problems with higher frequencies. (You might have noticed regulator reference designs do just that to assure a stable output. Now you know why.)

Design the error out. This approach will take the most engineering effort, since the goal is to change the design so that the error is no longer significant. The proverbial op-amp is an example of this type of effort. [10] Now that we know how to deal with the problem, let’s look at some common parts and typical sources of error. This will be an overview based on personal experience. It is no substitute for curing insomnia with a good datasheet.

电阻器#

Resistors

我得说,在三种基本元件中,电阻器是最稳定、最可预测的。碳膜电阻器的电感和电容都非常小。除非你是在处理射频或高速时钟,否则几乎不会出现相关问题。在大多数情况下,PCB 设计造成的影响都要大于电阻本身。

这些常见电阻器的最大问题可能是发热。如果超过或接近额定功率,它们的阻值就会明显偏离标称值,因此最好在功率设计上给自己多留一些余量。

另一种常见的电阻器,通常用于高功率应用,是线绕电阻器,其内部是一圈绕线,外部是陶瓷封装。在这种情况下,由于线圈的存在,电感效应可能会很显著。而我们知道,线圈就会产生电感。为了解决这个问题,现在有一个完整的低电感功率电阻器产业可供选择。

I would have to say that resistors are the most stable and predictable of the three basic components. Carbon film resistors have very little inductance or capacitance. It is rare that you will have a problem with this unless you are dealing with radio frequencies and high clock speeds. In most cases the effect of the PCB design will be worse than the resistor itself.

The biggest issue with these common resistors will likely be heat. Exceeding or coming close to the wattage rating of these parts will make them vary significantly from their nominal value, so it is a good idea to give yourself plenty of headroom with these resistors.

Another common resistor typically used in higher-power applications is a wirewound coil with a ceramic block molded around it. In this case inductance can be a significant effect since there is a coil of wire and, as we know, coils of wire make inductors. There is a whole industry of low-inductance power resistors that you can get to work around this problem.

电容器#

Capacitors

根据我的个人经验,我从未见过一个接近完美的电容器。一个完美的电容器不会发热,但现实中它们确实会发热。你自然可以得出结论:电容器具有某种电阻成分。事实上,它们确实有,这种成分被称为 ESR,即等效串联电阻。

根据公式,一个 10μF 的电容器在 100kHz 时应该具有与 0.1μF 电容差不多的阻抗,但现实却并非如此。这就是为什么你经常会看到电源电路上一个大电容旁边配着一个小电容。几乎所有的电容在不同频率范围下电容值都会变化。

大电解电容经常会像筛子一样“漏电”。对此没有特别容易的处理方式。你要么忍受它,要么换个更好的元件。相信我,如果你正试图做一个超低功耗的电路,最糟糕的事情就是电容四处乱“漏”电子。

还有一件我吃过苦头的事是:电容器的标称电容值只有在额定电压下才有效。有时候,电压额定值选得太高,实际电容值可能和你预期的不一样。如果你不按极性标注给极性电容加偏置,它们就会表现得像一个二极管。许多电容器的电容值在温度变化范围内会变化 20%;你可能不希望它们被放在 PCB 上靠近功率电阻的位置。

电容器的寓意:为特定应用选择电容器时,你需要仔细阅读其数据手册。

In my personal experience, I have never seen a cap that even comes close to being perfect. A perfect cap would not heat up, but in fact they do. The natural conclusion you should come to is that capacitors have some type of resistive component. In fact they do, and it is called ESR, or equivalent series resistance.

According to the equations, a 10-μf cap should have nearly the same impedance at 100 K Hz as a 0.1 μf cap does, but alas this is not the case. That is why you often see a large cap with a small cap next to it on a power-supply circuit. Nearly all caps vary in capacitance over a frequency range.

Big electrolytic caps often“leak” like a sieve. There is no particularly easy way to deal with that. You have to live with it or get a better part. Believe me, if you are trying to make a really low-power circuit, the last thing you want is a cap spilling electrons all over the place.

One other thing I had to learn the hard way is that a cap only meets the rated capacitance when at the rated voltage. Sometimes overrating the voltage on the cap too much can leave you with a different capacitance than you expect. Polarized capacitors will act like a diode if you don’t bias them according to their markings. Many caps will vary 20% over their temperature range; you might not want them next to a power resistor on your PCB.

The moral of the cap story: You need to peruse capacitor datasheets carefully when you are picking them for a particular application.

电感器#

Inductors

因为电感器通常是绕线制成的,所以你可以想象电阻是它们最常见的误差来源之一,你猜对了。电阻确实是电感器的主要误差源。这通常会导致发热和功耗问题,或许你并不希望出现这些问题。在设计阶段尽量减小电感器中的电流,就可以减小电阻的影响。

很多电感器是绕在某种铁芯材料上的。当磁场超过铁芯能承受的限度时,就会发生所谓的磁芯饱和现象。

导线之间存在一些电容效应,但非常微小,本书中将忽略它们。如果你正在处理千兆赫频率,那你可能正在读一本比我聪明得多的人写的专门书籍。

Since these are most often coils of wire, you might imagine that resistance is one of the most common sources of error in an inductor, and you’d be right. Resistance is a major source of error in inductors. This usually causes heat and power usage that you may or may not want. Minimizing the current flow through the inductor makes the resistance less of an effect and is something you might be able to do at the design stage.

Many inductors are warped around some type of ferrous core. An effect called core saturation occurs when the magnetic field exceeds the amount the core can handle.

There are some capacitive effects between the coils of wire, but they are so small that we will ignore them in this text. If you are cranking out the gigahertz needed to make this important, you are probably reading a book about this stuff written by someone much smarter than I am.

半导体#

Semiconductors

每个二极管以及基于二极管的所有半导体都会有一个压降。例如,如果你的晶体管放大器的基极电压不到 0.7V,你就无法让它正常工作。

轨到轨运算放大器比其前辈更昂贵,因为它们采用了可以消除这些压降的电路,从而让输入和输出都能达到电源轨。

在这些器件的数据手册中,你应该注意输出阻抗和电容效应。电感效应在半导体中通常较小、可以忽略不计。

热也会在半导体中引发误差。它通常会影响内部电阻,并可能引发雪崩式 [11] 故障。我还发现,最常被忽视的设计部分是散热。那些能轻松计算出所需电阻功率的工程师,往往会忽视半导体器件的热功率消耗。用流过元件的电流乘以两端的电压降,你就可以得出其耗散的功率。

就像雪崩一样,一旦开始失效,一切都会失控,通常还会伴随一种“有趣的”气味。

Like an avalanche, when it starts to fail all hell breaks loose, usually resulting in an interesting smell.

半导体的世界如此广泛复杂,这部分内容不可能涵盖全面。我听起来像是个跳针的老唱片(或许该说是刮花的 CD?),但我还是得说:请参考数据手册。

One of the things that every diode, and every semiconductor based on the diode, has in it is a voltage drop. For example, if your transistor amplifier doesn’t see a base voltage over 0.7 V, you won’t get it to work.

Rail-to-rail op-amps are more expensive than their predecessors because they employ circuitry that eliminates these voltage drops so that outputs and inputs can get to their power rails.

In the datasheet of these parts, you should look for output impedances and capacitive effects. Inductive effects are generally small and insignificant in semiconductors.

Heat can also cause error in semiconductors. It generally affects the internal resistance and can cause avalanche [11] failures. It also seems to me that the most often overlooked part of the design is heat dissipation. The same engineers who can easily calculate the wattage needed for that specific resistor value will overlook the amount of heat dissipation in a semiconductor. Take the current through the part times the voltage drop across it and you will see how much power is being dissipated.

The world of semiconductors is so widely varied that there is no way this overview can be anywhere near comprehensive. I have to sound like a broken record (or should I say scratched CD?) and tell you to refer to the datasheet.

电压源#

Voltage Sources

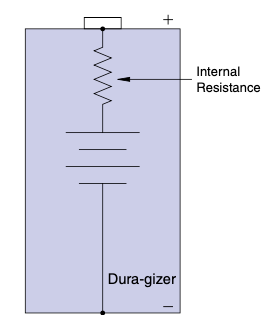

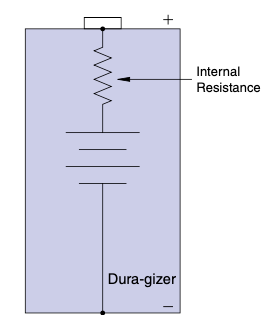

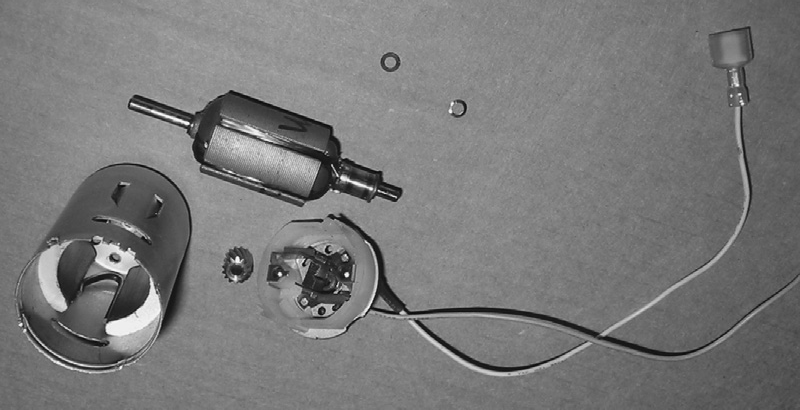

是什么导致电压源无法维持输出电压?让我给你个提示:当被加载时,电压源会发热。那么是什么产生热量?没错:电阻。电压源具有内部电阻。电池就是一个很好的例子——见 Figure 4.9。

图 4.9 Dura-gizer;这才是真正坚固的电池!#

当电流加到负载上时,电压会在这个内部电阻上产生压降,就像分压规则所描述的那样。这个内部电阻就像外部的电阻一样发热,使电压源变热。如果电源没有补偿这种效应,你将会在输出端看到较低的电压。

What would cause a voltage source not to maintain the voltage output? Let me give you a hint: When put under load, a voltage source will heat up. So what creates heat? You got it: resistance. A voltage source has an internal resistance. A battery is a good example—see Figure 4.9.

FIGURE 4.9 The Dura-gizer; now that is one tough battery!#

As current is applied to the load, the voltage drop occurs across this internal resistance, just like the voltage divider rule says it will. This resistor inside heats up just like one on the outside does, making the voltage source warm. If the source doesn’t compensate for it, you will see less voltage at the output.

当元件不完美时的结论#

When Parts Aren’t Perfect Conclusion

元件就是不完美的。我见过电机轴承因为电容效应过早磨损,也见过电容器过热后顶部爆裂。真正最好的做法是不断查看数据手册。器件工程师尽力将器件的不足之处加以表征,并写进数据手册供你查阅。

Parts simply aren’t perfect. I have seen motor bearings wear out prematurely due to capacitive effects and have seen caps overheat and pop their tops. Truly the best thing to do is keep looking at the datasheet. Parts engineers do their best to characterize the deficiencies of the part and put it in the datasheet for you.

拇指规则(Thumb Rules)

永远要问:这个元件中的误差源是否足以引起我看到的现象?

如果误差源不足以构成问题,那就忘了它继续前进。

修复误差时,要么换个更好的元件,要么加强它,要么设计上规避。

电容随频率变化。

电感有内部电阻。

半导体有压降和热问题。

电压源有内部阻抗。

数据手册看得越多越好。

Always ask, is the error source in this component enough to cause the effect I am seeing?

If the source of error isn’t large enough to be an issue, forget about it and move on.

When fixing errors, get a better part, shore it up, or design it out.

Caps vary with frequency.

Inductors have internal resistance.

Semiconductors have voltage drops and heat issues.

Voltage sources have internal impedance.

You can’t study the datasheet too much.

稳健设计#

ROBUST DESIGN

大多数工程师希望设计得过于保守,给自己留足裕量,使用远高于实际所需规格的器件。通常管理者会说:“成本要更低,否则卖不出去”,或“你真的真的需要那个器件吗?”老实说,答案介于这两个极端之间。

Most engineers want to overdesign, give themselves plenty of headroom, and use parts that are double or triple the spec they need. Usually the manager is there saying,“It needs to cost less or it won’t sell,” or “Do you really, really need that part?” To be honest, the answer lies somewhere between these extremes.

你能容忍它吗?#

Can You Tolerate It?

让我们从一个完全泛泛而谈的说法开始,你可能会从一个发型尖锐、有点狡黠的人那儿听到这样一句话:“一个稳健的设计能很好地应对两件事:内部世界和外部世界。”你额头立刻写满困惑的表情。“这是什么意思?”你心想。让我来解释这段尖酸语言的含义。

内部世界是构成设计的所有元件。在任何生产过程中,这些元件的参数都会有所变化。你要问的是:“电路能否在这些元件的公差范围内正常工作?”如果答案是肯定的,那么设计在内部是稳健的。内部世界没问题。不过不要以为只有电子元件才有公差。这个道理通过实例讲述最合适。曾经我参与一个项目,我们用一个光学传感器检测皮带的运动。我们正确分析了传感器的公差,但在试产过程中我们发现皮带的不透明度有变化。如果光传感器处于其公差的高端,而皮带又是最透明的状态,那么传感器的信号就不会足够高,无法确保逻辑输入正确读取。

在大批量生产中,这类问题会表现为随机故障。这类故障被称为公差堆叠。当两个或多个元件的参数变化叠加,最终导致故障时,就是公差堆叠。这比单一元件的公差问题更难分析。预防这种故障最好的办法可能是借助仿真器。不过要小心:在你开始做公差分析之前,请确保你的仿真模型能准确代表使用了理想元件的设计。(关于仿真器的更多建议,见后续章节。)仿真器最大的优势就是能够在不制造一堆实物的情况下,模拟所有元件的公差变化并查看效果。这样你就可以调整设计和元件规格,从内部角度提高产品的稳健性。

而外部世界则是另一回事了。一个好的设计能够应对外部世界施加的各种影响。在电子领域,各种干扰都有可能破坏你的设计。我曾读过一篇文章,里面描述了一种“生锈锉刀测试”。工程师在测试完器件后,将其插入墙上的插座,同时插入自制测试夹具。该夹具由从 AC 中性线引出的导线连接到一把锉刀。火线一端剥了皮,然后他开始将它在这把旧锈锉刀上上下摩擦,火花四溅。[12] 如果电路能顺利通过这个测试,他就认为这东西没问题。这就是 EMI,也就是电磁干扰。这确实是一个庞大的主题,因此我专门为此写了一个章节。如果你迫不及待,直接跳到 第6章 吧!

你对外部世界的关注不应仅限于电气干扰。很多情况下,其他因素也会引发问题。例如,震动可能导致 PCB 上的走线断裂,焊点失效。湿度上升可能导致廉价 PCB 膨胀,从而造成机械变形和连接断裂。湿度也可能与杂质结合,在你不希望短路的电路上引起电气短路。温度对电子元件的影响尤其严重。你应当检查电路将会处于的温度范围,并与数据手册中的规格比较。不要忘记在分析中包含设备本身的工作温度。例如,功率器件在正常工作时本就会很热。如果你再把它放在 70ºC 的环境中,就很容易超过其最大温度规格。

作者是 Ron Mancini,发表于 EDN。但我要强调:请不要在家尝试这个测试。有很多比它更安全的方法。我提到这个测试,只是为了给你留下深刻印象,说明外界干扰到底有多“混乱”。

It was written by Ron Mancini in EDN, but I have to say: Do not try this test at home. There are much safer ways than the procedure described; I mention this test because it creates a vivid picture of the junk out there that is trying to mess up your circuit.

那么你该如何从外部提升设计的稳健性呢?可以采取几种做法:

在我看来,最重要的是从基础设计上尽你所能,使其适应所处环境。通常对 PCB 布局做一些调整,比把它用各种屏蔽包起来更能抵御 EMI。更宽的走线可以抵抗机械变形,而几个位置合适的散热孔可以帮助管理温度。

接下来最重要的事情可能就是不断阅读你使用元件的数据手册。你越了解你使用的元件,就越能识别出可能破坏设计的问题。

第三种最全面的努力,就是测试、检查、测试、再测试你的设计。你需要重现电路将处于的各种环境,并观察它的表现。

此外,还可能出现一种情况,即问题来自内部设计的公差和所处环境效应的叠加。这类情况几乎无法预知,通常只能在实际使用过程中被发现。你唯一能做的是:找出预防它的方法,进行更改,并将其记录下来,以供将来类似设计参考。

我建议每位工程师和每个工程组都保留一份设计指南文档 [13],记录那些你在设计过程中发现的经验法则。不要只写下来,而要定期阅读它,这样你在每一次新设计时都能牢记它们。这本身就是一个非常强大的工具。几年前我接手一个工程团队。刚开始时,我们几乎每天都被叫去产线解决各种奇怪的问题,花在支持生产上的时间远远超过开发新产品。

我喜欢把它们称为“关卡”。如果一个设计能顺利通过这些规则和测试的关卡,我才会认为它达标。

I like to call them gauntlets. If the design can run the gauntlet of passing guidelines and tests, that is when I deem it good enough.

我们开始专注于稳健设计原则,我实施的第一项措施就是编写设计指导文档。每次我们发现一个新的设计准则,就将它记录下来,并定期查看,确保在每一个新设计中都能落实。

在三年左右的时间里,这些紧急电话开始逐渐减少。我们从花超过 50% 的时间支持生产,减少到不到 10%。再过几年,支持生产的问题降到不到 1%。要知道,我们每天出货数万件产品,这可是一项巨大的成就。原本每天都会接到电话的我们,几个月都不会接到一次。即使偶尔出现问题,也几乎总能追溯到我们写过但没遵守的某条准则。最难的部分变成了在每次新设计时回头查看这些文档。既然如此,我建议你不要让你的设计准则文档太庞大。文档越大,你就越不愿去读。所以尽量控制在几页以内,毕竟它总有扩展的倾向。

为了量化外部世界可能带来的影响,很多标准文档被制定出来。虽然它们读起来很催眠(五分钟就能让你昏昏欲睡),但它们能让你真正了解你的设计将会受到哪些外部影响。我指的是像 IEEE 62.41(描述 EMI 世界)或 UL 991(描述如何保证控制系统的安全)这类文档。这类文档还有很多。花点时间研究你正在做的内容,看看是否有人写过相关文档。如果你的老板不理解你为什么要花时间阅读这些资料,就把下面这段话给他看:

老板,看起来工程师坐着读资料像是在摸鱼,但相信我, 这项投入能为你节省数百万的生产停工成本。 给你的工程师一个成功的机会,你一定不会后悔。

工程师,这不意味着你就只读不设计。我建议把这类研究控制在总设计时间的 10% 到 20%;如果你做的是从未做过的项目,可以适当翻倍。

这些资料在你彻夜难眠、思考自己设计哪里出了问题时尤其有用。我会把它们放在床边。这样我可以在睡前学习几分钟,也能顺便安然入睡。它们不仅能帮助你设计电路,还能治疗失眠!

Let’s start with a completely general off-the-wall statement that you might hear from someone with a sharpened, somewhat devilish hairdo:“A robust design handles two things well: the inside world and the outside world.” A look of consternation scrambles across your forehead.“What in the world does that mean?” you ask yourself. Let me proceed to enlighten you on this bit of pointy-speak.

The inside world is all the parts that make up the design. In any production pro- cess, these parts will vary in specification. The question to ask is,“Will the circuit operate correctly over the tolerance ranges of the parts?” If the answer is yes, the design is robust internally. The inside world is good to go. Don’t assume, how- ever, that only electronic components have tolerances. This point is best taught by example. In a design I worked on some time ago, we were using an optic sen- sor to detect the motion of a belt. We correctly analyzed the tolerance of the sensor, but as we began testing on a pilot run we discovered that the belt we were using varied in opacity. If the optic sensor was at the high end of its tolerance and the belt was at its most transparent, the signal from the sensor wouldn’t get high enough to guarantee that the logic input would read it correctly.

In a production run, a problem like this would appear as a random failure. This type of failure is known as a tolerance stack-up. It occurs when the stack- up (the additive effect of the variations) of two or more components combine to create a failure. It is more difficult to analyze than a single-component tol- erance issue. Probably the best way to preempt this type of failure is with the help of simulators. Take caution, though: Make sure that your simulation accu- rately represents the design with nominal perfect components before you start running tolerance analysis on it. (See the section on simulators for more sug- gestions.) The great thing about a simulator, though, is the ability to vary all the components over their tolerances and see the effects without building a whole bunch of parts. You can then adjust your design and component specs to increase the robustness of the product as far as the inside world is concerned.

Now the outside world is a different animal. A good design can handle the things the outside world throws at it. In the electronic realm all sorts of inter- ference can disrupt your design. I once read an article that described something called a rusty file test. After the engineer was done with the part, he would plug it into the wall and plug in a home-built test fixture next to it. It consisted of a wire from AC neutral connected to a file. The hot wire had a bare end that he would proceed to rub up and down the rusty old file, sparks flying everywhere. [12] If the circuit passed this test without a hitch, he figured it was good to go. This is known as EMI, or electromagnetic interference. It really is a whole topic unto itself, so I have dedicated a chapter to it. Skip ahead to Chapter 6 if you can’t handle the suspense!

Don’t limit your focus on the outside world to electrical interference. There are many cases where other things can cause a problem. Vibration, for example, can cause traces on a PCB to crack and solder joints to become faulty. Increased humidity can swell a cheap PCB, causing mechanical deformation and cracked connections. It can also combine with debris to create electrical shorts on cir- cuits that you don’t want shorted. Temperature can be particularly tough on electrical components. You should review the temperature range your circuit will be subject to and compare that to the specs in the datasheet. Don’t forget to include the operating temps of the device you are using in this analysis. For example, power components usually get pretty warm just operating. Toss them into a 70ºC ambient and you could easily push them over the max tem- perature spec.

How do you go about making your design robust externally? There are several approaches to take:

The most important, in my opinion, is doing everything you can in the fundamental design to get it to handle the environment it is in. Often a few changes to the PCB layout itself can make a circuit handle EMI better than putting all the shielding around it you can fit. Larger traces can combat mechanical deformation, and a few wellplaced holes can help manage temperatures.

Reading, reading, and rereading the datasheet for the component you are using is probably the next most important thing you can do. The more you know about the parts you are using, the better you will recognize things that might upset your design.

The third and most extensive effort that will help you is to test, check, test, and retest the design. You need to recreate the environments that it will be subject to and see what happens.

Now, to top it off, you can have a situation where the problem is a combination of the tolerance of the internal design and the environmental effects it is subject to. These situations are nearly impossible to predict and are often sim- ply discovered in the course of business. There is only one thing you can do about that: Figure out what is needed to prevent it, make the change, and docu- ment it for future use on similar designs.

I recommend that every engineer and engineering group keep a document of design guidelines [13] where you write down those rules of thumb that you dis- cover along the way. Don’t just write it down, but read it regularly to keep those things you have learned fresh as you do each new design. This alone can be a powerful tool. Some years back I took over an engineering group. When I first started managing it, it seemed like we were always being called to the produc- tion line for some weird problem or another. We spent more time chasing pro- blems than engineering new products.

We began to focus on robust design principles, and one of the first things I implemented was the design guideline documents. Every time we found a new design rule to follow, we wrote it down and referred to it regularly so that it would be implemented with each new design.

Over about a three-year period, those urgent calls to production began to drop off. We went from spending over 50% of our time in production support to spending less than 10%. A couple years after that, we were spending less than 1% of our time dealing with production problems. Considering that we were moving tens of thousands of products out per day, it was a great achievement. Months would go by without a call, where before we got calls every day. When problems did occur you could nearly always trace back to a guideline that we had written down and simply neglected to follow. The hard part became refer- ring back to those documents each time we created a new design. That being the case, I suggest you try not to let your guidelines get too large. The bigger these documents, the less likely you are to read through them. So try to keep them to a few pages, since they will have a tendency to grow a lot.

In an effort to quantify what the outside world can do, many standards have been written. They are some great yawners (meaning they will knock you out in about 5 minutes of reading); however, they can give you some real insight into what your design will be subject to from the outside in. I’m referring to documents like IEEE 62.41, which describes the world of EMI, or UL 991, which describes how to make a control safe. The list goes on and on. Do a little research into what you are working on and see if someone has written something about it. If your boss doesn’t understand the need for time to do this, show him this paragraph:

Boss, it might seem like nothing is getting done when the engineer is sitting there reading, but trust me, this effort can save you millions in production downtime, so give your engineer a chance to succeed and you will not regret it.

Engineer, this doesn’t mean that you should just read and never design any- thing; I would limit this research to about a 10 to 20% ratio of design versus research; double it if you are doing something you have never done before.

Reading these documents works particularly well if you are tossing and turning all night as you try to figure out what is wrong with your design. I would keep them by the side of my bed. That way I could learn some more for a few minutes and also get some sleep. They not only help with the design, they are a great cure for insomnia!

学会适应#

Learn to Adapt

你是否曾在完成一个产品设计之后,被要求做出某些更改,而你多么希望这些更改能在一开始就被告知?你是否曾说过:“如果你早点告诉我,现在加上这个功能的成本可以减半?”甚至你的老板还可能会说:“你怎么没做我让你做的事情?”(而你明明已经完全照他的意思做了)。让我告诉你一个秘密:大多数那些尖头发型的老板并不希望你失败。他们只是希望推出一个牛X的产品,以便他们能拿到更高的奖金。

他们没早点告诉你,是因为他们自己也不知道。他们只能尽力猜测客户想要什么,然后去满足它们。在老板的脑海中,他并没有说:“做某某产品”,他是说:“让这个产品成功。”随着公司不断追逐市场,新产品被开发、被更改、再被更改。我把这种情况称为“管理永远在追赶市场”(Management Always chasing the Market Around),简称 MAMA。(如果你想让别人记住一个观点,没有什么比缩写更有效的了。我预言未来某天,缩写会成为最主要的沟通方式,因为它高效!)正因如此,许多工程师在产品定义更改时都会感到困惑。

在消费电子产品领域,这种情况经常发生。当我在第一家公司接手工程组时,这种挫败感常常存在。随着我与公司各个设计师的合作,我发现可以提前预测这些更改并为之做准备。当你擅长这件事时,你可以轻松而快速地应对更改,还能以更快更低的成本开发出一系列派生产品。

Have you ever finished a product design after which some change was required that you desperately wished you had been told about at the beginning? Have you ever said,“If you had just told me sooner, this feature would have cost half as much to add on now?” You might even have had your boss say,“Why didn’t you do what I told you to do?” (when you did exactly what he or she wanted). I’ll let you in on a secret: Most of your pointy-haired bosses don’t want you to fail. They just want to ship a killer product so their bonus will be bigger.

They don’t tell you sooner because they don’t know sooner. They try to guess what the customers want and give it to them. In his mind your boss didn’t say, “Do such and such a product,” he said,“Make this product successful.” As companies chase the market around, new products are developed, changed, and changed again. I call this Management Always chasing the Market Around, or MAMA for short. (There is nothing like an acronym if you want a point to be remembered. I predict that some day in the far future acronyms will be the prime method of communication due to their efficiency!) Now, because of MAMA, many engineers experience consternation when their product definition changes.

In the world of consumer products, this is bound to happen often. When I took over the engineering group in the first company I worked for, this particular frustration was often felt. As I worked with the various designers in the company, I found that it was possible to anticipate these changes and prepare for them. When you get good at this, you can respond to changes easily and quickly, and you can also develop a number of derivative products quickly and inexpensively.

模块化设计#

Modular Design

为了预测更改,最重要的事情之一就是对你的设计进行模块化。在这方面,硬件设计师可以向软件设计师学习。优秀的软件工程师会构建可以反复使用的代码模块。但我常常看到硬件设计师每次新设计都从空白纸开始。

为了让模块化设计为你所用,你必须评估你正在设计的产品。是否有某些组件经常在各种设计中被替换或重复使用?哪些部分在你所有或大多数产品中是共通的?坐下来画大量方块图,然后问自己:“这是一个需要容易拆装的部分吗?”如果是,那它可能就是一个候选模块,可以放在独立的 PCB 上,或在 PCB 上划出独立的区域。例如,在一系列音响产品中,你可以将调谐器部分与前置放大器分开等等。(顺带一提,这种方式通常也能提升设计的稳健性。)

这种模块化方法的一个巨大优势是,它允许不同的工程师分别开发不同的模块,从而加速整个开发过程。它还允许你在不重做整个设计的前提下,升级或改进设计的某些部分。在我的领域中,最重要的是——它让你在老板突然决定不想在这个型号上加某个功能时,轻松做出更改。

不过,需要警告一句:你必须谨慎选择要模块化的部分。模块太多会导致你每一个出货产品的成本都上升。 确保你的选择是有意义的。

One of the most important things that you need to do to anticipate change is to modularize your designs. Here, hardware designers can take note from their counterparts in software design. Good software engineers build blocks of code that can be used and reused again and again. However, I often see hardware designers start with a clean sheet for every new design.

To make your modular design work for you, you must evaluate the products you are designing. Are there any components that are commonly removed and installed on various designs? What parts are common to all or most of your products? Sit down and draw lots of block diagrams and ask yourself,“Is this a part that needs to be easy to take on and off?” If it is, it might be a candidate for a separate PCB or a section of the PCB all to itself. In a line of stereo products, for example, you keep the tuner section separate from the pre-amp and so on. (As a side note, this often improves the robustness of a design as well.) A great advantage of this modular approach is the way it can accelerate the development process by using separate engineers on the various modules. It also allows you to upgrade or improve parts of the design without redoing the whole thing. Most important in my world and best of all, it makes it easy to change a feature when your boss decides he really didn’t want that there on this particular model.

One word of warning, however: You need to be careful what parts you choose to modularize. Too many modules can add up to extra cost in every product you ship. Make sure your choices make sense.

预测更改#

Anticipate Changes

尽量参与产品创建过程,这样你就能看到产品设计经历的各种演化阶段。通常,更改会是在这些演化路径上前后反复。不断问自己:“这个还能用在哪?我需要怎么改才能适应那里?”

注意哪些地方好像缺了一个部分。例如,假设你被要求设计一个带有一排 LED 的 PCB,如 图 4.10 所示。你说“好,没问题”,然后像 图 4.11 那样设计 PCB,并暂时不安装那个“缺失”的 LED。

别犹豫,告诉同事或老板你在做什么。他们在预测他们自己日后可能提出的更改时,可能会成为你的宝贵资源。最关键的是,每次都重新设计产品需要大量的工作量,但如果你在设计产品时能开发出有效的模块并预测更改,那么你就能比别人更快、更便宜地将产品推向市场。这种预见性设计的一个额外好处是,当你被要求开发一个类似产品时,你已经有所有必要的模块在手。你只需添加或移除某些功能即可搞定。最后也是最棒的一点:MAMA 将不再逼疯你!

图 4.10 管理层想要的一排 LED。#

图 4.11 实际放入的一排 LED。#

Try to get involved in the creation process so that you can see various phases of evolution the product design has gone through. Often, changes that are made will be back or forth on this evolutionary path. Keep asking yourself,“Where else could this be used? How would I change it to work there?” Look for places where a part seems to be missing. For example, say that you are asked to make a PCB with a row of LEDs that look like Figure 4.10. Say“Great, no problem,” and then create a PCB with this row of LEDs, as shown in Figure 4.11, and simply do not install the missing one for now. Don’t hesitate to tell your coworkers or boss what you are doing. They can be a great asset in anticipating changes they might come up with later. The bottom line is that it takes a tremendous amount of work to redesign every product every time, but if you can develop effective modules and anticipate changes when you are engineering the product, you can bring things to market faster and cheaper than anyone else. A nice benefit of this type of anticipative design is that when you are asked to develop a similar product, you have all the pieces in place. You simply add or subtract the required feature and are done with it. Finally, best of all, MAMA will not drive you berserk!

FIGURE 4.10 Row of LEDs management wants.#

FIGURE 4.11 Row of LEDs you actually put in.#

最后一个警告#

One Last Word of Caution

采取这种设计理念当然是好事,但也可能走得太远。不要让你的设计为了追求通用性而导致产品无法及时上市,或者因加入太多可选功能而使产品不再具备商业可行性。记住,有些你提前设计好的选项,也许永远都不会被使用。因此,明智地选择吧,年轻的绝地武士。 [14]

It is possible to go too far with this philosophy. Don’t try to make your design so universal that it comes at the expense of getting the product to market or adds so much cost for all the options that it is no longer viable. Remember, there is also a chance you will never use the option you built in, so choose wisely, young Jedi. [14]

拇指规则(Thumb Rules)

阅读数据手册。

考虑元件公差。

了解使用环境。

测试、检查、再测试。

编写你自己的拇指规则或设计准则清单。

查阅与你产品相关的已有标准或指导文件。

MAMA 可能令人沮丧。

模块化你的设计。

预测可能的更改。

不要走得太远。

Read the datasheet.

Consider tolerances.

Know the environment.

Test, check, and retest.

Make your own list of Thumb Rules or design guidelines.

Do research on standards or guidelines that exist for your product.

MAMA can be frustrating.

Modularize the design.

Anticipate changes.

Don’t go too far.

我最喜欢的一些电路#

SOME OF MY FAVORITE CIRCUITS

每个工程师都有自己最喜欢的一批电路,我也不例外。市面上有大量电路宝典,教你如何实现各种酷炫功能。它们太多了,以至于你可能一直在查阅它们,而永远做不出任何实际成果。我建议你自己积累一些最基础、最喜欢的电路,对它们了然于心、直觉掌握。这其实是我们在本书开头所讲的“乐高哲学”的自然延伸。下面是我最喜欢的一些电路,除了前面章节中作为示例出现的电路以外。它们之所以是好例子,就是因为它们非常实用。

绝地心灵感应在职场中有用吗?我觉得有用。这或许可以写成一本很酷的书。如果你愿意购买,欢迎发邮件告诉我。如果收到足够多的反馈,我一定会认真考虑这个点子!

Do Jedi mind tricks work in the cooperate world? I think so. Now, that is a cool idea for a book. Email and let me know if you would buy it. If I get enough responses I definitely will explore that idea!

Every engineer has their favorite batch of circuits, and I’m no exception. There are tons of circuit cookbooks out there that show how to implement no end of cool features. There are so many that you could spend all your time searching them and never getting anything done. I suggest you develop your own favorite basic circuits that you know well and intuitively understand. This is simply an extension of the Lego philosophy that we discussed way back at the beginning of the book. Here are a few of my favorites. These are in addition to all the cir- cuits I have used as examples up to this point. One reason they make such good examples is that they are so useful.

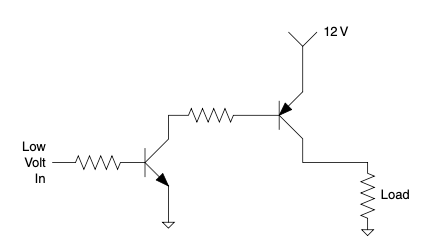

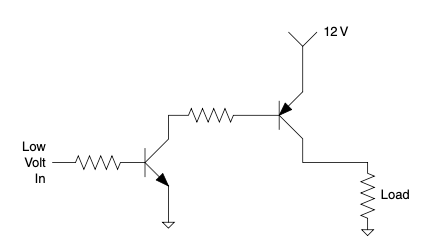

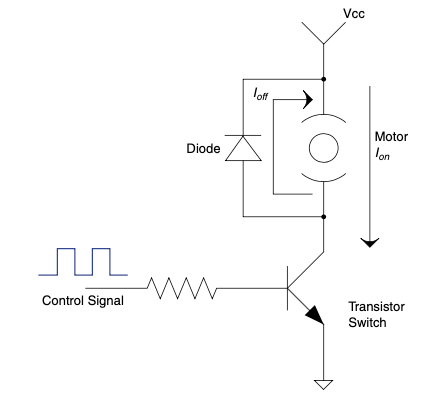

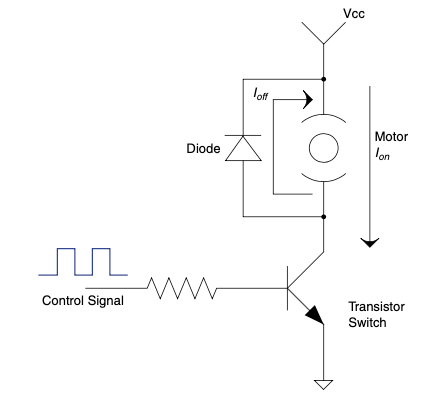

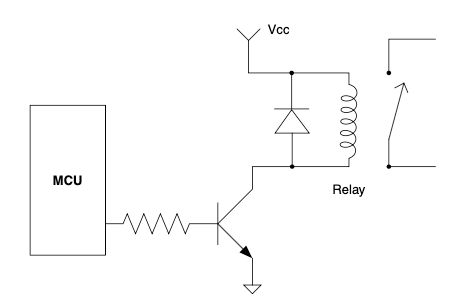

混合达林顿对#

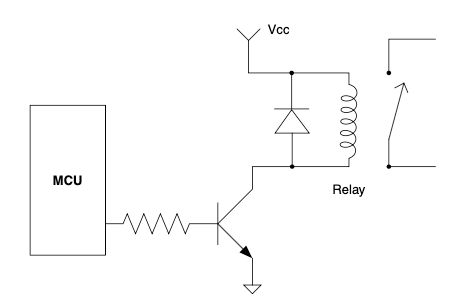

Hybrid Darlington Pair

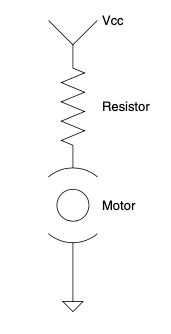

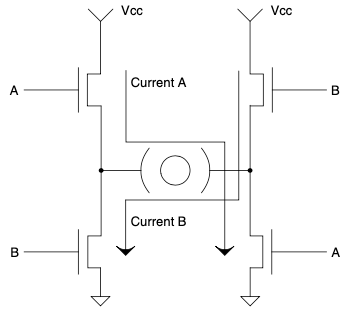

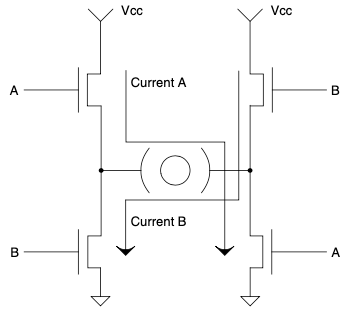

一个很酷的应用笔记:使用两个晶体管来切换一个由 NPN 控制的 Vcc PNP 电平信号。

图 4.12 展示了一个实用电路,它可以用较低电压来切换较高电压。例如,你有一个输出为 5V 的微控制器,但你需要驱动一个 12V 的负载。由于某些你无法更改的原因,你必须切换 Vcc 端。在这个电路中,你使用 5V 信号打开第一个晶体管,它随后激活另一个晶体管,从而将较高电压切换到负载上。

图 4.12 NPN 控制的 Vcc PNP。#

这个电路之所以有效,是因为晶体管是电流驱动的;当你切断流向 PNP 晶体管的电流时,它就会关闭,无论电压如何。另一个优点是,该电路具有类似达林顿对的特性,但没有其缺点之一。你不需要向输入端提供大量电流即可切换输出,而且与传统达林顿对不同的是,输出端的电压降要小得多。你不需要处理输出端串联的两个基极结。如果你仍然不明白,不妨用一点 ISA [15] 来分析。

直觉信号分析(ISA)。我仍希望有朝一日能用一个缩写为我立下不朽之业。

Intuitive signal analysis (ISA). I still hope to someday cement my legacy in an acronym.

Cool application note: using two transistors to switch a signal level Vcc PNP switched by NPN.

Figure 4.12 shows a handy circuit that switches a higher-level voltage with a lower-level one. Say, for example, you have a micro with a 5 V output and you need to drive a 12 V load. For a reason you can’t change, you have to switch the Vcc leg. In this circuit you turn on one transistor with a 5 V signal, which in turn activates the other transistor, switching the higher voltage to the load.

FIGURE 4.12 Vcc PNP switched by NPN.#

This works because the transistors are current driven; when you shut off the current flow to the PNP transistor, it shuts off regardless of the voltage. Another plus is that this circuit has Darlington-like properties without one of the downsides. You won’t need a lot of current to the input to switch the out- put and, unlike a traditional Darlington pair, the voltage drop across the out- put is much smaller. You don’t have two series base junctions to contend with at the output. If you still don’t follow, try a little ISA [15] on it.

直流电平转换器#

DC Level Shifter

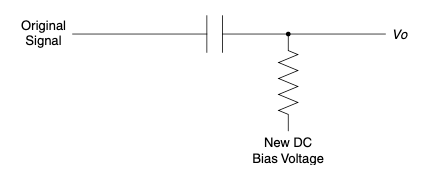

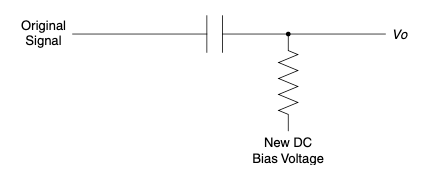

这实际上是我们之前学过的高通滤波器,但做了一点变化,如 图 4.13 所示。不是将电阻接地,而是连接到一个参考电压。由于直流的频率为零,只有 交流 成分会通过,在这个过程中,一个直流偏置会被施加到信号上。请确保你所选择的电容和电阻不会使你想要的信号被过度衰减。

图 4.13 改变交流信号上的直流偏置。#

This is really the high-pass filter that we have already studied but with a slight twist, as shown in Figure 4.13. Instead of ground, we hook the resistor to a refer- ence voltage. Since DC has a frequency of zero, only the AC component will pass and in the process a DC bias will be applied to the signal. Make sure that you don’t size the cap and resistor so that the signal you want is attenuated.

FIGURE 4.13 Change the DC bias on an AC signal.#

虚地#

Virtual Ground

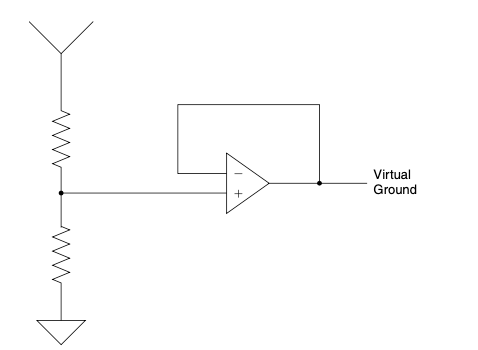

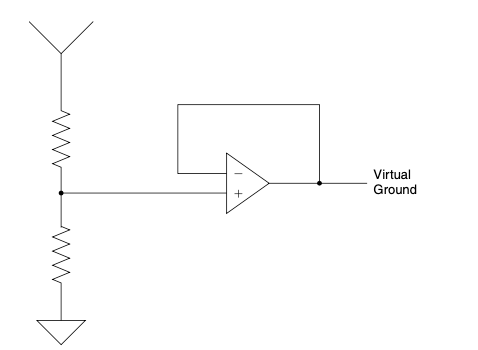

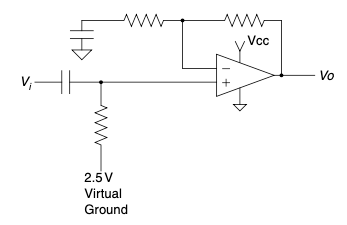

使用电压分压器作为参考,运算放大器就变成了一个电压源,其输出等于分压器上的电压——见 图 4.14。当你想用单电源电路处理 交流 信号时,这会非常有用。

图 4.14 在你想要的电平上创建一个“地”。#

Using the voltage divider as a reference, the op-amp becomes a voltage source with the output matching the voltage at the divider—see Figure 4.14. This can be very useful when you are trying to handle AC signals with only a single-ended supply circuit.

FIGURE 4.14 Create a“ground” at any level you want.#

电压跟随器#

Voltage Follower

如 图 4.15 所示,当你试图测量一个容易受负载影响的信号时,这个电路非常有用。Vi = Vo,但最重要的是,由于运算放大器的缓冲作用,Vi 完全没有被加载。

图 4.15 电压跟随器。#

As Figure 4.15 shows, this one is mighty useful when you’re trying to measure a signal that is easily affected by load. Vi= Vo, but, best of all, Vi isn’t loaded at all, thanks to the buffering effect of the op-amp.

FIGURE 4.15 Voltage follower.#

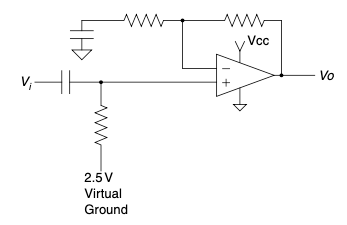

仅交流放大器#

AC-Only Amplifier

图 4.16 展示了另一个优秀电路,它在用单电源放大 交流 信号时表现良好。它还有一个好处:不会放大任何直流信号成分,从而避免诸如直流偏移等问题使你的信号上轨。这是因为反馈电路中的电容。由于电容只传递 交流 电流,直流信号会视该点为断开。当接地电阻断开时,运算放大器就像前一个电路中的电压跟随器一样工作。

图 4.16 仅交流放大器。#

Figure 4.16 shows another great circuit that works nicely in amplifying AC signals with a single-ended supply. It also has the benefit of not amplifying any DC signal components, keeping things like DC offsets from making your signal rail. This happens because of the cap in the feedback circuit. Since the cap only passes AC current, DC signals see that point as disconnected. When the resistor to ground is disconnected, the op-amp acts like the voltage follower in the previous circuit.

FIGURE 4.16 AC-only amplifier.#

反相振荡器#

Inverter Oscillator

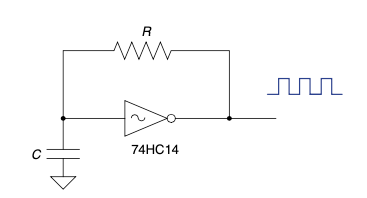

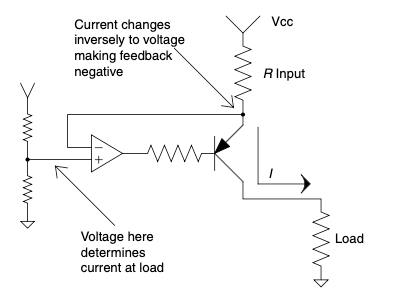

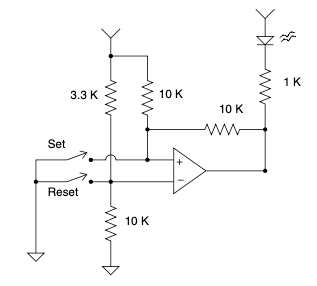

多年前我在一本数据手册的最后看到这个电路;我记得那是摩托罗拉的逻辑数据手册。那时候还没有互联网,你必须真正翻页去找这些东西!这个电路的工作原理基于施密特触发器反相器的输入具有迟滞特性(图 4.17)。这使得输出会保持在高或低电平,直到输入端电容充电到触发反相器的阈值电压。输出翻转,一切反向,周而复始地重复。如果你在充放电路径中加入一些二极管,可以影响输出的占空比。

图 4.17 施密特触发振荡器。#

I saw this in the back of a data book years ago; I think it was a Motorola logic data book. This was way back before the Internet. You used to have to turn actual pages to find this stuff! The way it works is based on the fact that the Schmidt trigger inverter has hysteresis built into the input (Figure 4.17). This makes the output stick at a high or low level until the cap on the input charges to the threshold voltage that trips the inverter. Out- put flips and everything goes in the other direction, repeating indefinitely. Adding some diodes to the charge and discharge path can affect the duty cycle of the output.

FIGURE 4.17 Schmidt trigger oscillator.#

恒流源#

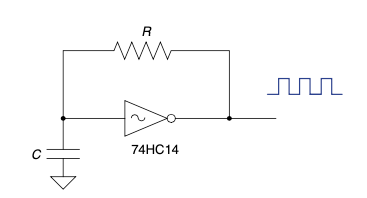

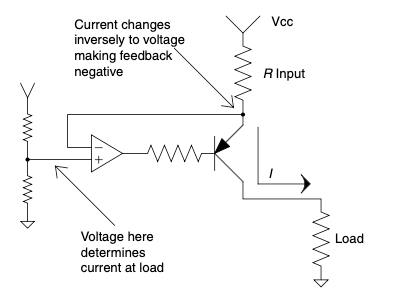

Constant Current Source

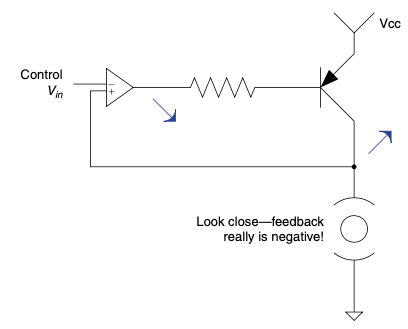

利用负反馈,运算放大器试图保持 R 输入上的压降不变。即使负载电阻发生变化,R 输入上的压降仍保持一致。根据欧姆定律,保持 R 和 V 不变,也就意味着电流保持不变——见 图 4.18。不过请记住,这种电流控制是有操作极限的;输出电压的摆动范围有限,无法无限补偿负载变化。一旦超出这些极限,就无法再保持恒流调节。

图 4.18 电压控制的恒流源。#

Using negative feedback, the op-amp tries to maintain the voltage drop across R input. Even if the resistance of the load changes, the drop across R input stays the same. According to Ohm’s Law, keeping R and V the same will keep current the same, too—see Figure 4.18. Remember, though, this current control has operational limits; it can only swing the output voltage so far to compensate for load variance. Once these limits are reached, the current regulation can no longer exist.

FIGURE 4.18 Voltage-controlled constant current source.#

拥有你自己的——这里有几个示例#

GET YOUR OWN—HERE ARE A FEW

我只有几个最喜欢的电路概念。拥有属于你自己的,并且熟知它们。深入了解几个电路概念,比浅尝辄止地知道成千上万个电路要更有用。

按照这个建议,第一版的几位读者寄来了他们喜欢的一些电路。下面不多说,直接呈现给大家。

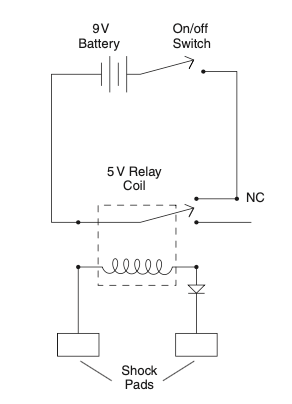

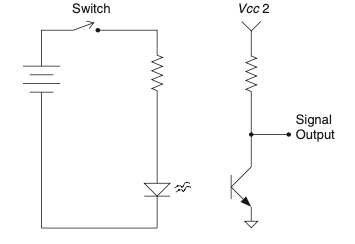

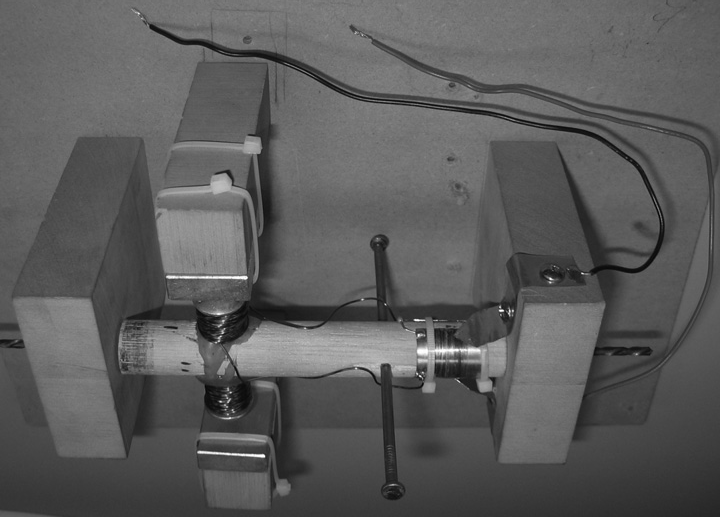

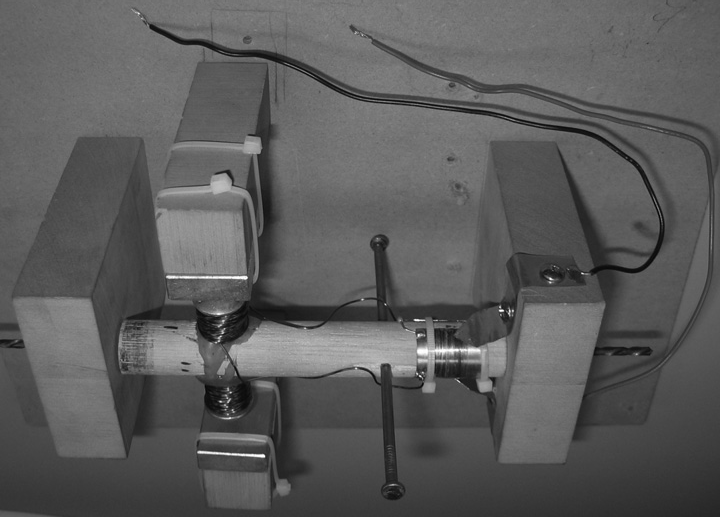

Steve Petersen 送来了 图 4.19 中所示的电路,他说这个电路派对上玩很有趣,还可以加上一个延时电路,当别人拿起装有该电路的有趣装置时,会被吓一跳 [16]。

图 4.19 玩具电击器电路。#

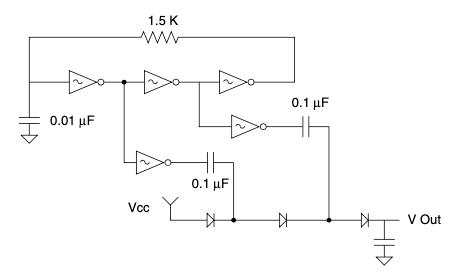

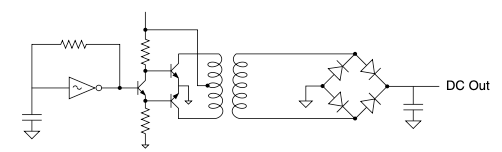

Travis Hayes 送来了 图 4.20 中的一个精巧小电路图,它使用了我列表中的反相振荡器来驱动一个电压倍增电路。他说这是为他使用的液晶显示器获得更高电压的一个非常灵巧且廉价的方法。我必须同意!

我在此声明,凡是有人因使用本书中的设计而受伤,我概不负责。虽然我在此脚注中努力提醒“请勿在家尝试!”我们这些书写作者是专业人士,懂得如何开玩笑而不真正伤害任何人,至少不会太严重!

I hereby claim no responsibility whatsoever for anyone out there hurting themselves using a design they found in this book when I took the effort in this footnote to say,“Don’t try this at home!” We book writers are professionals and know how to do a practical joke without really hurting anyone, at least not too badly!

图 4.20 反相器驱动的电压倍增器。#

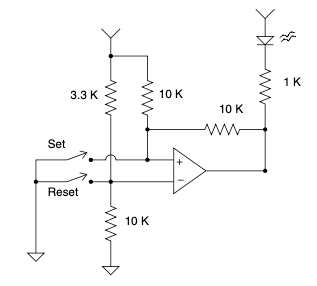

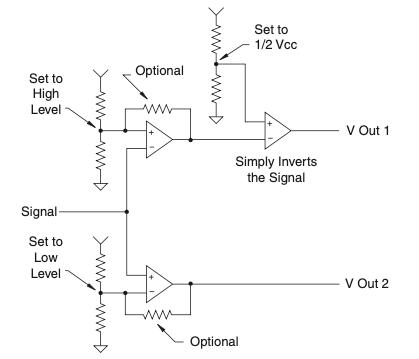

图 4.21 触发器存储运放电路。#

Alan Tyger 可能和我一样是运放的铁粉。他寄来了 图 4.21 中的电路图,使用了这样的器件来存储一条信息。

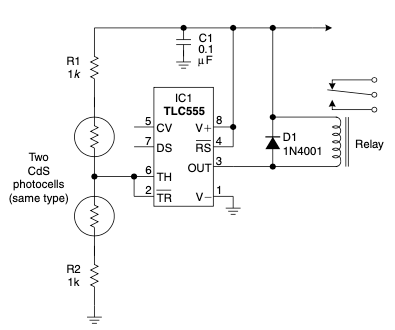

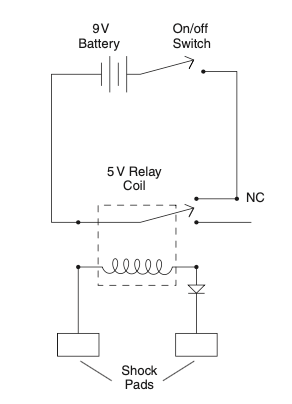

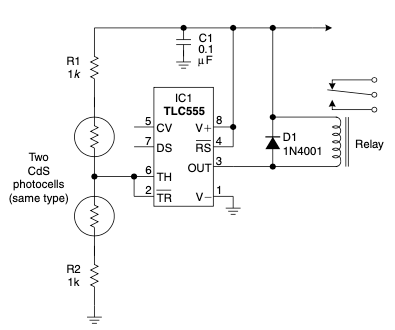

Michael Covington [17] 送来了 图 4.22 中的酷炫电路;它将遥控的乐趣和激光指示器结合起来。555 定时器作为存储单元(和 Alan 的电路类似),但这个电路额外增加了使用激光控制的功能。多酷啊!我不知道哪个工程师不喜欢激光,我敢肯定他们回家看电视时都得控制遥控器。

该电路发表于上世纪 90 年代末我为《Electronics Now》杂志撰写的“问答”专栏中。出版方已授权转载。

This circuit was published in the“Q&A” column of Electronics Now some time in the late 1990s when I was writing that column for the magazine. The publisher has given permission to republish it elsewhere.

用激光笔照射任一光电池即可切换状态。供电电压不敏感(根据继电器要求为 5 到 15 V)。注:为平衡光电池性能并在强光条件下获得更好表现,可省去 R1 或 R2 中的一个(但不能同时省去)。#

图 4.22 激光光控开关。

Mike Angeli 送来了 图 4.23 中的酷炫电路。他说用它结合电位器反馈来定位负载(因此需要高阻抗)。

Sam Nay 送来了 图 4.24 中的电路,他说他一直对无线上传输数据的能力感到着迷。我敢打赌他接上了刚才看到的激光控制开关。另外,我还知道一个秘密电路,虽然不便透露,但它用的光学电路变体与这个类似,可用于生物识别采集。真希望我能给你看看那个,不是吗?

最后,Mourly Thov 送来了 图 4.25 中的电路。他说这是一种巧妙的方法用来改变直流电压(并具有一定的功率容量,这可能是 Travis 电路中的一个问题),所以如果你需要一个可以提供一定电流的不同电压,不妨试试这种方案。

最后,我要说的是,通过与这些工程师的交流,我觉得他们都属于 RSP [18] 类。或者说,可能只是因为他们给我发了邮件,而且非常喜欢本书第一版。无论如何,我感谢他们的投稿,并完全免责,任何这些电路能否实际工作均由你自负。希望它们能带给你好运,帮你填满一本你自己的最爱电路笔记。

请查阅本书后面的术语表。我敢打赌你也认识一些 RSP!

Look it up in the glossary at the back of this book. I’ll bet you know some RSPs too!

图 4.23 激光光控开关。#

图 4.24 激光光控开关。#

图 4.25 激光光控开关。#

经验法则

保持你自己的酷炫电路手册。

熟悉它们。

I have just a few favorite circuit concepts. Get your own and know them well. You will be better served knowing a few circuit concepts inside-out than know- ing thousands superficially.

Following this advice, several readers of the first edition sent in some of their favorite circuits. Without further ado, they are presented next. Steve Petersen sent in the circuit shown in Figure 4.19, saying something about being fun for parties and the potential to add a delay circuit to really surprise someone [16] when they picked up whatever interesting device the circuit was embedded in.

FIGURE 4.19 Toy shocker circuit.#

Travis Hayes sent in the diagram of a sleek little circuit, as shown in Figure 4.20, that uses the inverter oscillator from my list to drive a voltage doubler circuit. He said it was a pretty slick and inexpensive way to get a higher voltage for an LCD he was using. I’d have to agree!

FIGURE 4.20 Inverter-driven voltage doubler.#

FIGURE 4.21 Flip-flop memory op-amp.#

Alan Tyger just might be as big a fan of op-amps as I am. He sent in the circuit diagram shown in Figure 4.21 ; it uses just such a device to store a piece of information.

Michael Covington [17] sent in the cool circuit shown in Figure 4.22; it combines the fun of remote controls with a laser pointer. The 555 acts as a memory cell (not unlike Alan’s circuit), but this one has the added bonus that you use a laser to control it. How cool is that! I don’t know any engineer who doesn’t like lasers, and I’m pretty sure they all have to control the remote when they are home watching TV.

Hit one or the other photocell with a laser pointer to change states. Supply voltage is not critical (5 to 15 V depending on requirements of relay). Note: Either R1 or R2 (not both) can be omitted to make up for imbalance between the photocells and provide better performance in bright-light conditions.#

FIGURE 4.22 Laser light switch.

Mike Angeli sent in this cool circuit in Figure 4.23. He said he used it to posi- tion a load using a potentiometer feedback (thus the high-impedance requirement).

Sam Nay sent in the circuit shown in Figure 4.24, saying he was always fascinated by the ability to transmit data without wires. I’ll bet he hooks up the laser-controlled switch that we saw just moment ago. Also, I happen to know of a secret circuit that I am not at liberty to disclose that uses a variation of optical circuits not that different from this one to take biometric readings. Bet you wish I could show you that one, don’t you!?

Finally, Mourly Thov sent in the circuit shown in Figure 4.25. He said he just thought it was a slick way to change the DC voltage (and have some power capacity, which could be an issue with the one Travis sent in), so if you find yourself in need of a different voltage that can move some current, try an idea like this one.

On a final note, I have to say that from my communication with these engineers, I think they all fall in the RSP [18] category. Then again, maybe that is just because they emailed me and really liked the first edition of this book. Either way, I thank them for their submissions and completely absolve myself from any responsibility for these circuits actually working. I hope they bring you luck and help you to fill up a notebook with your favorite circuits.

FIGURE 4.23 Laser light switch.#

FIGURE 4.24 Laser light switch.#

FIGURE 4.25 Laser light switch.#

Thumb Rules

Keep your own cookbook of cool circuits.

Learn them well.

电源#

POWER SUPPLIES

无论你用电子技术做什么,都需要电力来完成。了解电源的基础知识非常有用,因为在你的职业生涯中几乎肯定会遇到它们。

Whatever you do with electronics, you are going to need power to accomplish it. It will be useful to understand the basics of power supplies, since you are nearly guaranteed to deal with them at some point in your career.

电压为王,宝贝!#

It’s All About the Voltage, Baby!

如今大多数设备都希望保持电压恒定。这意味着电流可以根据需要变化。在电力领域,尤其是涉及无处不在的集成电路(IC)时,你常常得不到完全想要的电压。

大量产品使用墙壁插座的120 V交流电(AC)供电。另一大批产品使用可从插座充电的电池,还有一些大量使用可以在大型超市买到的电池。问问自己,去年圣诞节你买了多少电池?

问题是,现在大多数集成电路需要5V、3.3V甚至1.5V直流电(DC)。这离120V相差甚远,而且绝不是交流电!这就需要电源供应器。电源分为两种类型:线性电源和开关电源。

Most devices today want to keep the voltage constant. This means that current can vary as needed. In the world of power, particularly as it relates to the ubiquitous IC, it often seems that you never have the exact voltage you want. A huge number of products run off 120 V AC out of a wall socket. Another huge group runs off batteries that are charged from those wall sockets, and another significant number runs off batteries that you can buy by the caseload at any super-duper-mart. Just ask yourself, how many batteries did you buy last Christmas? The problem is that most ICs these days want 5, 3.3, or even 1.5 V DC. This is nowhere near 120 V, and definitely not AC! Enter the power supply. They come in two flavors, linear and switcher.

线性电源#

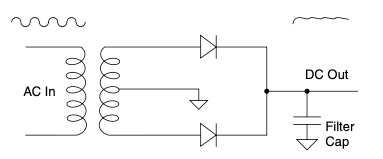

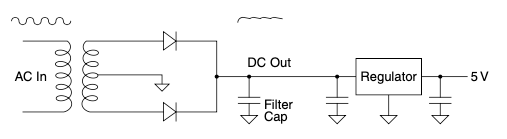

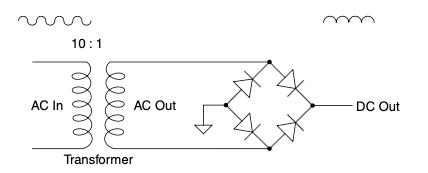

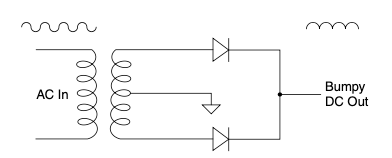

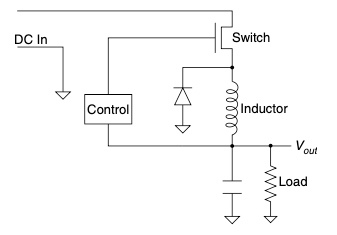

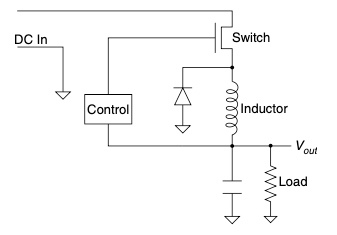

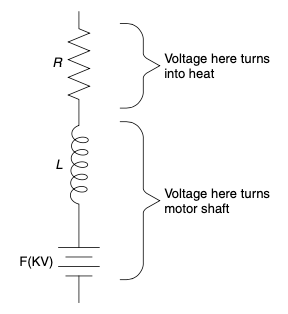

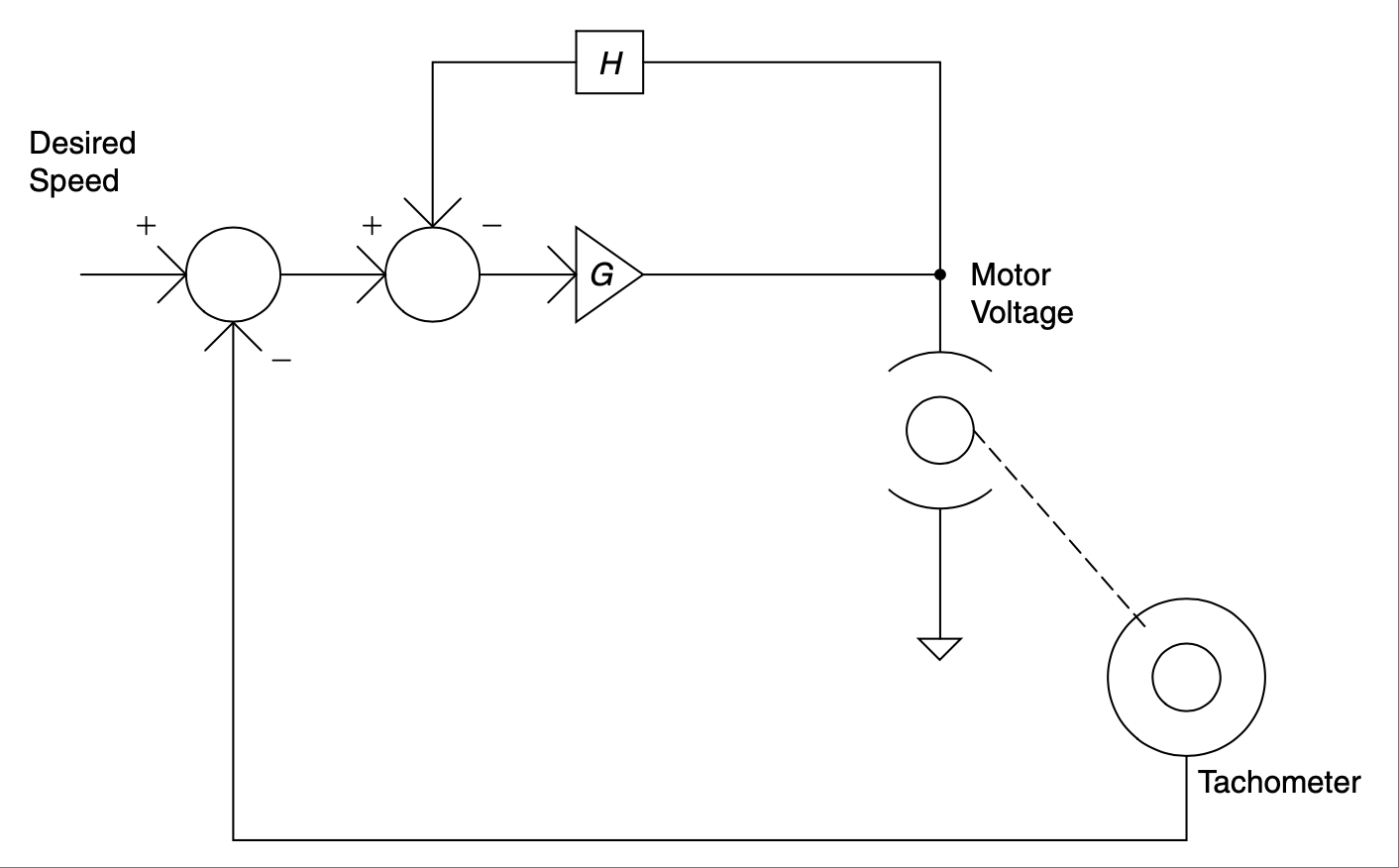

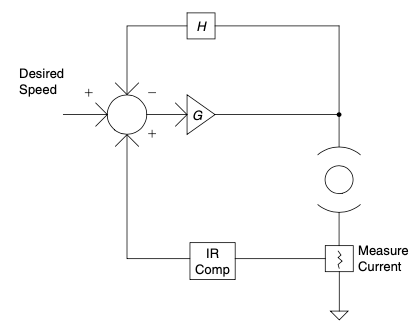

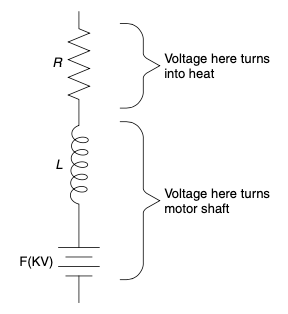

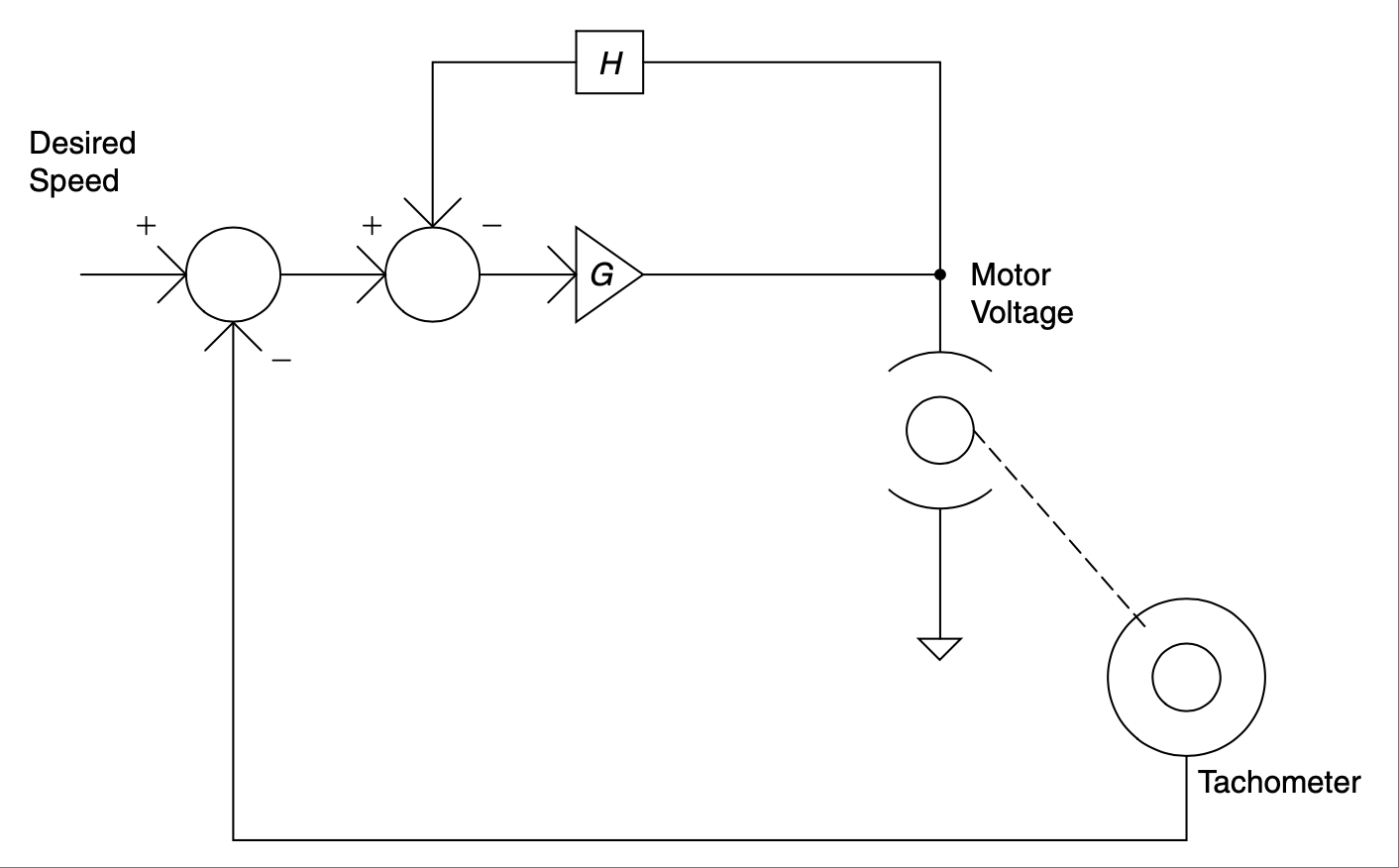

Linear Power Supplies